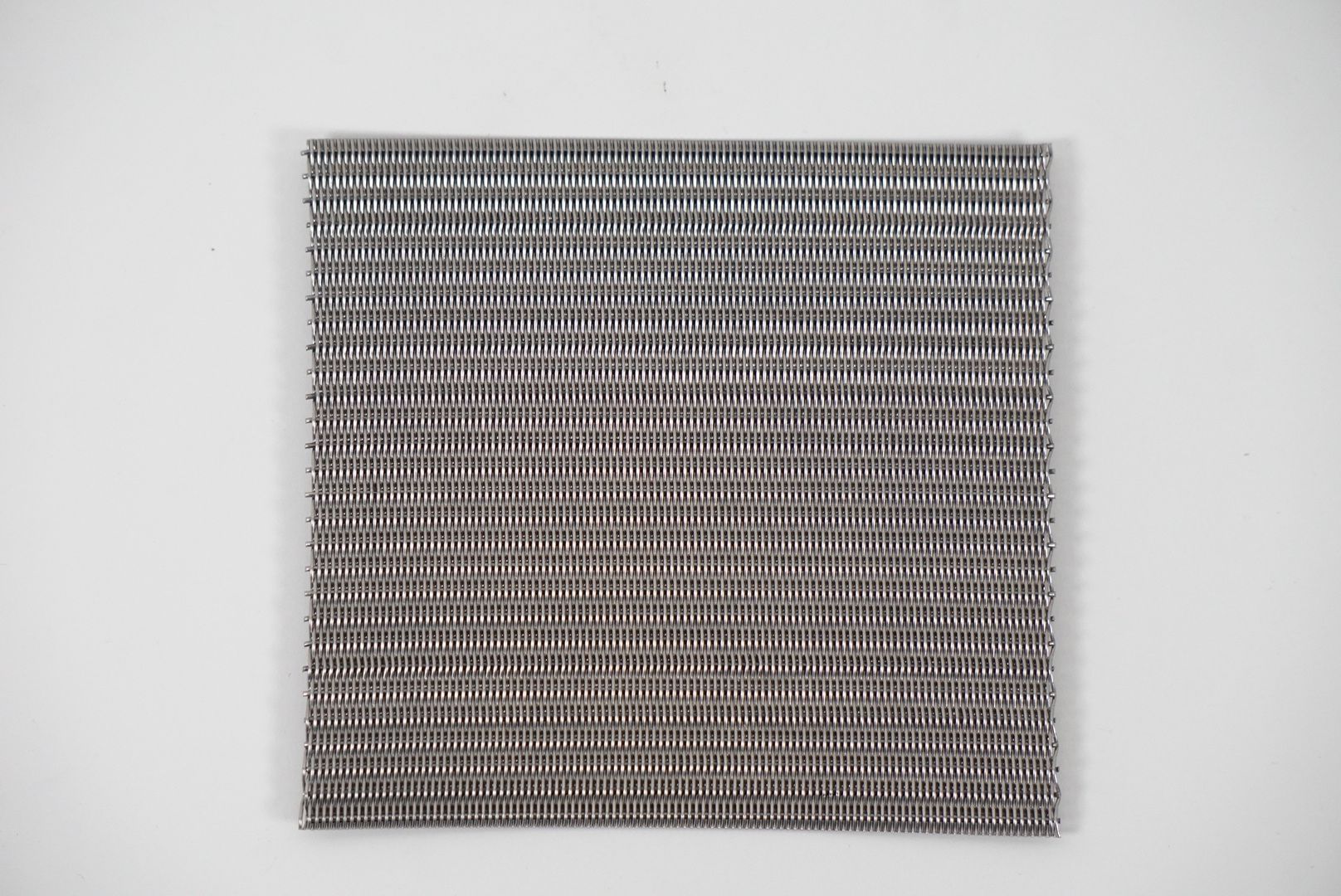

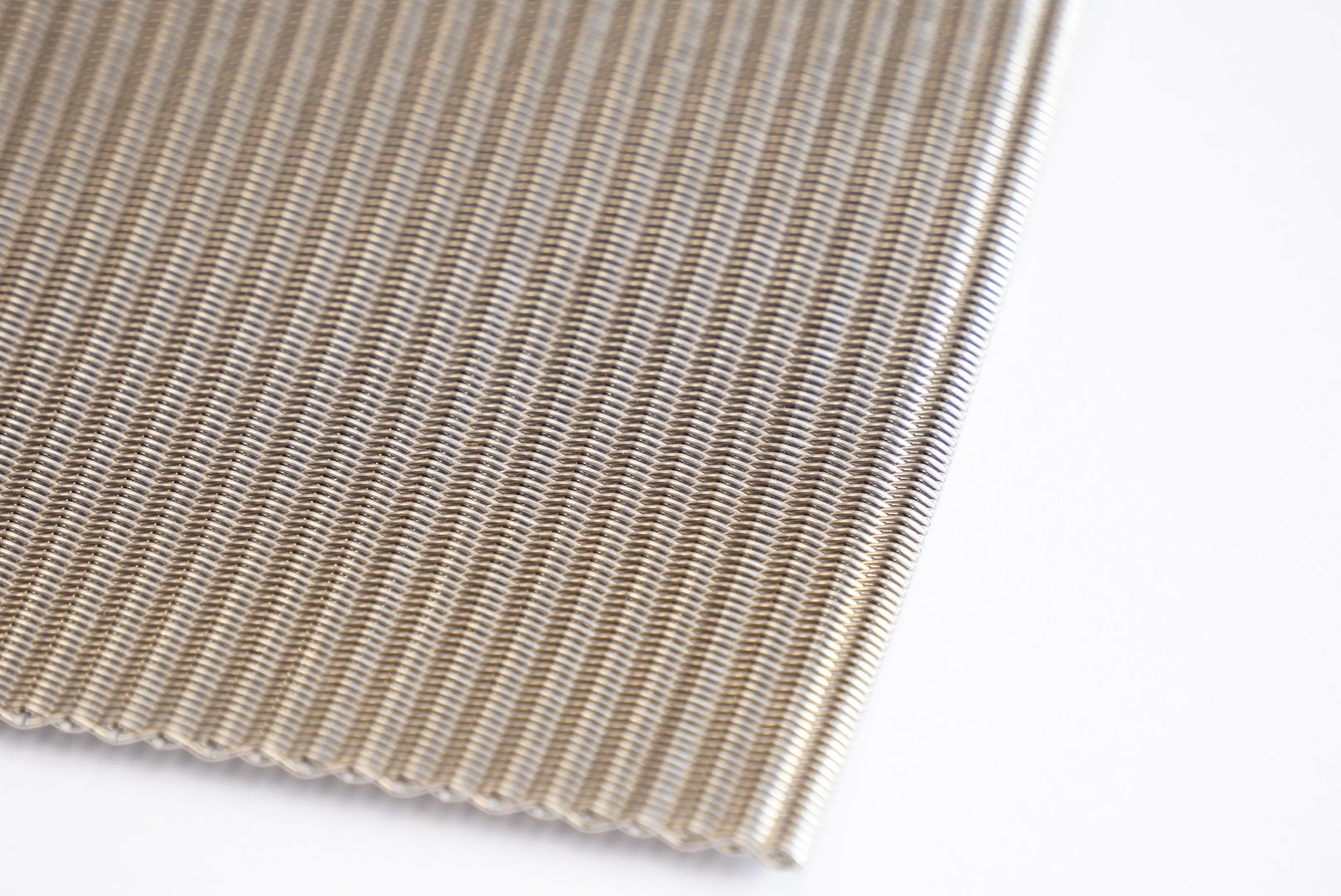

DUTCH weaving

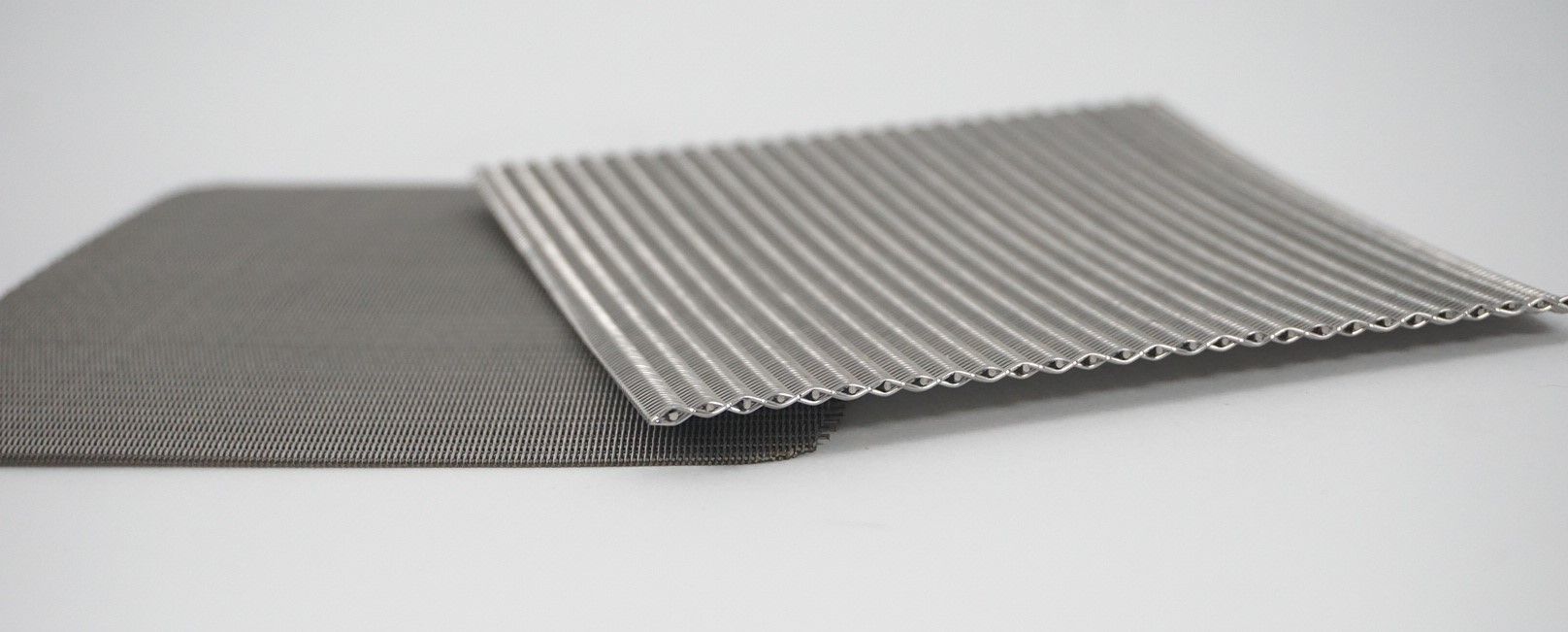

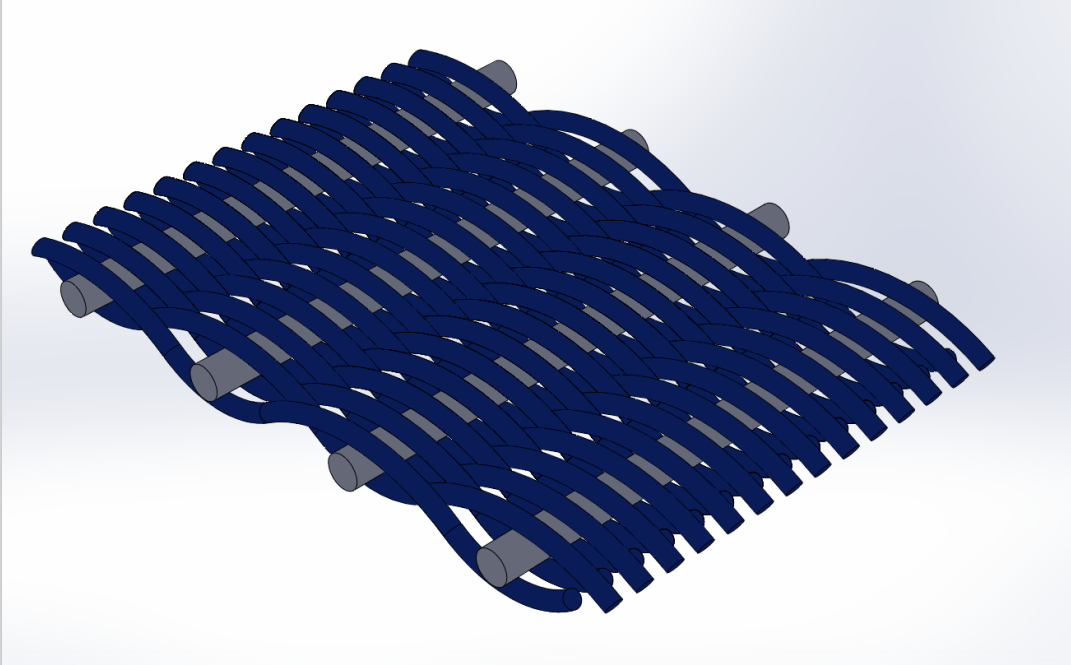

Dutch weaving is very common in industry, mainly for filtration and extrusion. It is characterised by adjoining warp threads (Warp dutch) or weft threads (Weft dutch) which, at their intersection, create a triangular opening. It features:

- High mechanical resistance to abrasion and pressure

- A filtration threshold starting at 6µ (dutch twilled 510 x 3600)

- Good porosity with regular openings

- High density and strong rigidity

Plain or twilled weft dutch is defined in NF X 11-515 standard.

Mesh can be sold in rolls of any width, in panels of any geometric shape and transformed into finished products (filters, discs, adv.) of any size.

The following information is needed to specify your mesh and determine its price.

- Raw material,

-

- Stainless steel Aisi 304, 304 L, 316, 316 L, 316 TI

- Stainless steel, magnetisable (430 adv.), refractory (321 adv.), super duplex (318 LN), adv.

- Annealed steel

- Nickel, brass, copper, gold, titanium, adv.

- Weft or roll width: from a few mm up to 3 meters.

- Warp or length of the roller: from a few meters to several hundred.

- Nominal opening, i.e. passage of a ball: from 6µ to 500µ.

- Wire diameters: of warp and weft wires.

- Heat treatment (hyperquenching, adv.).

- Expected finish (degreasing, packaging, adv.).

Often, you will have a couple of numbers (ex: 24 x 110) that defines your mesh.

It corresponds to the number of threads per inch (Fr = 27.78 mm / Uk = 25.40 mm) for the warp, then the weft. The nominal opening is calculated by dividing the inch value (Fr or Uk) by the smallest number, then dividing the result (the pitch or centre-to-centre distance) by 7. So, for a dutch 24 x 110:

(25.4 / 24) / 7 = 0.151 mm, i.e. a filtration threshold of approximately 150 µ

Fr and Uk Dutch do not necessarily match.

Wire diameters are seldom given. They can influence the opening.

We are ISO 9001 certified and meet the requirements of NF X 11-515 standard.

It is the guarantee to get a product of consistent quality, with all required certificates: measurement, material, alimentarity, adv.

SAULAS has a stock of standard Dutch meshes to ensure best availability. Our flexible, responsive organisation allows to quickly weave your mesh. (Subject to wire availability)

Wire mesh is our core business and has been manufactured since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. More than 8,000 customers in France and abroad have already placed their trust in us.