Perforated sheets

Meshes and filter components, sieves and all parts we produce can be made from a very wide range of materials, depending on the properties required and the environments in which they are used:

- Breaking resistance

- Deformability

- Thermal and/or electrical conductivity

- Machinability and weldability

- Corrosion resistance (marine environment, acid, alkaline, adv.)

- Thermal resistance

- Alimentarity, aesthetics

- Magnetic and electromagnetic properties

We can use the following materials to achieve this:

- Stainless steels

- Conventional stainless steels Aisi 304, 304 L, 316, 316 L, 316 TI

- Stainless and special steels, magnetisable (430 adv.), refractory (321, Inconel adv.), duplex and super duplex (318LN, 1.4410), 317L, 330, Uranus, 904L, Incoloy, Monel, Hastelloy, adv.

- Hyper-hardened stainless steels

- Steels and coated steels

- Annealed or high strength (HR) steel

- Galvanised steel

- Epoxy coating, rilsan coating

- Non-ferrous metals and their alloys

- Nickel, brass, aluminium, copper, titanium, gold

- Cupro Nickel, Nitronic

- Synthetics:

- Polyamide

- Polypropylene

- Polyester

- Polyethylene

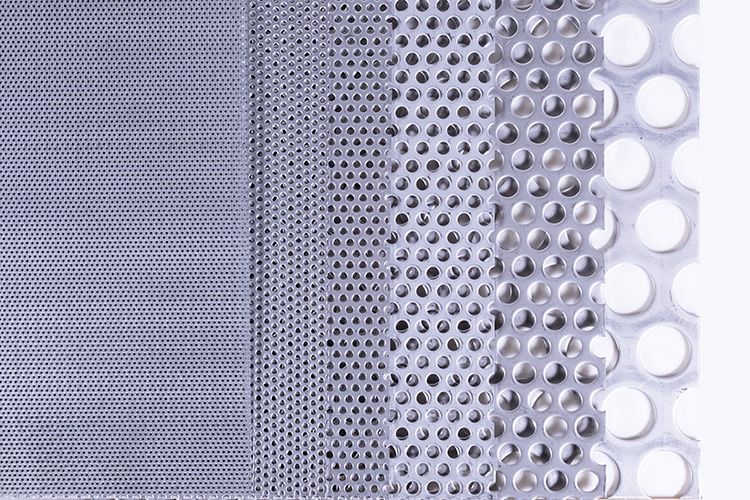

Micro-perforated plates

Beyond the family of perforated plates of which minimum perforations are close to plate thickness (approximately Ø1.00mm in 1mm thickness), it is possible to produce micro-perforated sheets with perforations of up to 25 to 40% of plate thickness (perforation of Ø 0.30mm in 1mm thickness), for very specific applications and using technical processes chosen according to the specifications.

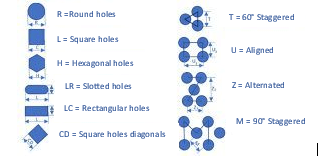

The different shapes and layouts of the holes

- Holes can be: Round, Square, hexagonal, slotted, rectangular and diamond.

- Layout can be: staggered at 60°, aligned, alternating, staggered at 90°.

- It is the combination of these 2 parameters that will specify the sheet, for example: R10T14, i.e. round holes Ø 10 mm staggered at 60° with a centre-to-centre distance of 14 mm, giving an open area of 46%.

Micro perforated sheet

The following information is needed to specify your mesh and determine its price:

- Raw material,

- Stainless steel Aisi 304, 304 L, 316, 316 L, 316 TI

- Stainless steel, magnetisable (430 adv.), refractory (321 adv.), super duplex (318 LN), adv.

- Annealed or high strength (HR) steel

- Galvanised steel

- Nickel, brass, copper, gold, titanium, adv.

- Holes shape and layout, for example: C3U5,

- Sheet thickness,

- Part dimensions quantity to be produced,

- Solid border or not on one or more sides,

- Required surface treatment and finish (degreasing, packaging, adv.),

- Required certificates (material, dimensions, adv.)

SAULAS is ISO 9001 certified and regularly invests in production tools to provide you with the best possible service rate. We have been based near Troyes (FR) since 1960 and are organised to respond quickly to your needs. More than 8,000 customers in France and abroad have already placed their trust in us.

Examples of perforations, from the smallest to the largest:

- From R 0.35 T 1.06 to R 326.9 Z 350×572

- From C 1.2 U 1.7 to C 125 Z 150×300

- From LR 0.3×10 U 1.4×13 to LR 70×100 Z 180×125