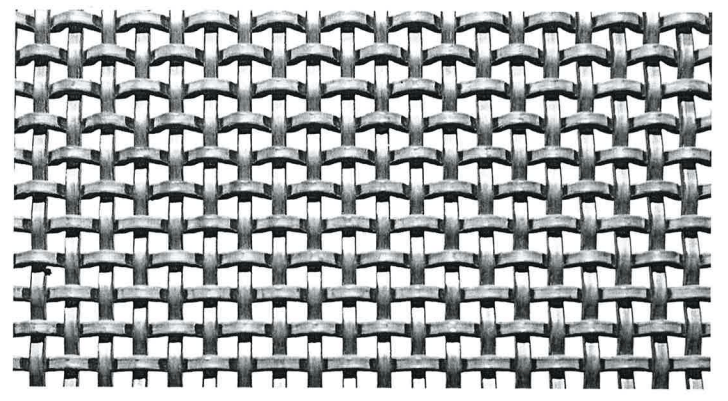

Wire mesh with 2 square wires

Some activities, such as sorting/cleaning cereals or seeds, decompacting clay to make ceramics or crushing cocoa beans and separating seeds from shells, require very strong meshes. Some will require sharp edges to make separation easier.

These meshes use round or square wires (featuring sharp edges), made of stainless steel or high-strength steel (with low carbon), with large diameters and meshes that can be small (a mesh / wire Ø ratio close to 1).

Depending on your dimensional characteristics, the mesh to wire diameter ratio and the type of wire, we will propose you either :

- A mesh with annealed thread, woven to ISO 9044 standard,

- Or a crimping weaving with preformed wire, when this is high resistance steel wire and/or with a low mesh / wire Ø ratio, woven in accordance to ISO 14315 and 4783-3 standards.

Mesh and crimping weaving can be sold in panels of any geometric shape and transformed into finished products (panels with hooks, frames, cylinders, adv.) of any size.

Following information is needed to specify your mesh and determine its price:

- Raw material,

- Stainless steel Aisi 304, 304 L, 316, 316 L, 316 TI

- Stainless steel, magnetisable (430 adv.), refractory (321 adv.), super duplex (318 LN), adv.

- High-strength steel

- Dimensions and characteristics of the product,

- Mesh size or nominal opening,

- Wire diameter,

- Wire shape

- Expected finish (degreasing, packaging, adv.).

Mesh or grid with square wires - warp and/or weft - are much more difficult to make and depend on the availability of wires. The range is fairly limited and lead times are generally long.

Some examples of mesh / grid :

- # 2.0 Ø 1.4 - # 1.4 Ø 1.4 - # 1.25 Ø 1.0 - # 1.2 Ø 0.8

We are ISO 9001 certified and meet the requirements of ISO 9044 (industrial mesh) and ISO 4783-2 (preferred combinations # and Ø) standards.

It is the guarantee to get a product of consistent quality, with all required certificates: dimensional, material, alimentarity, adv. Wire mesh is our core business and has been manufactured since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. More than 8,000 customers in France and abroad have already placed their trust in us.