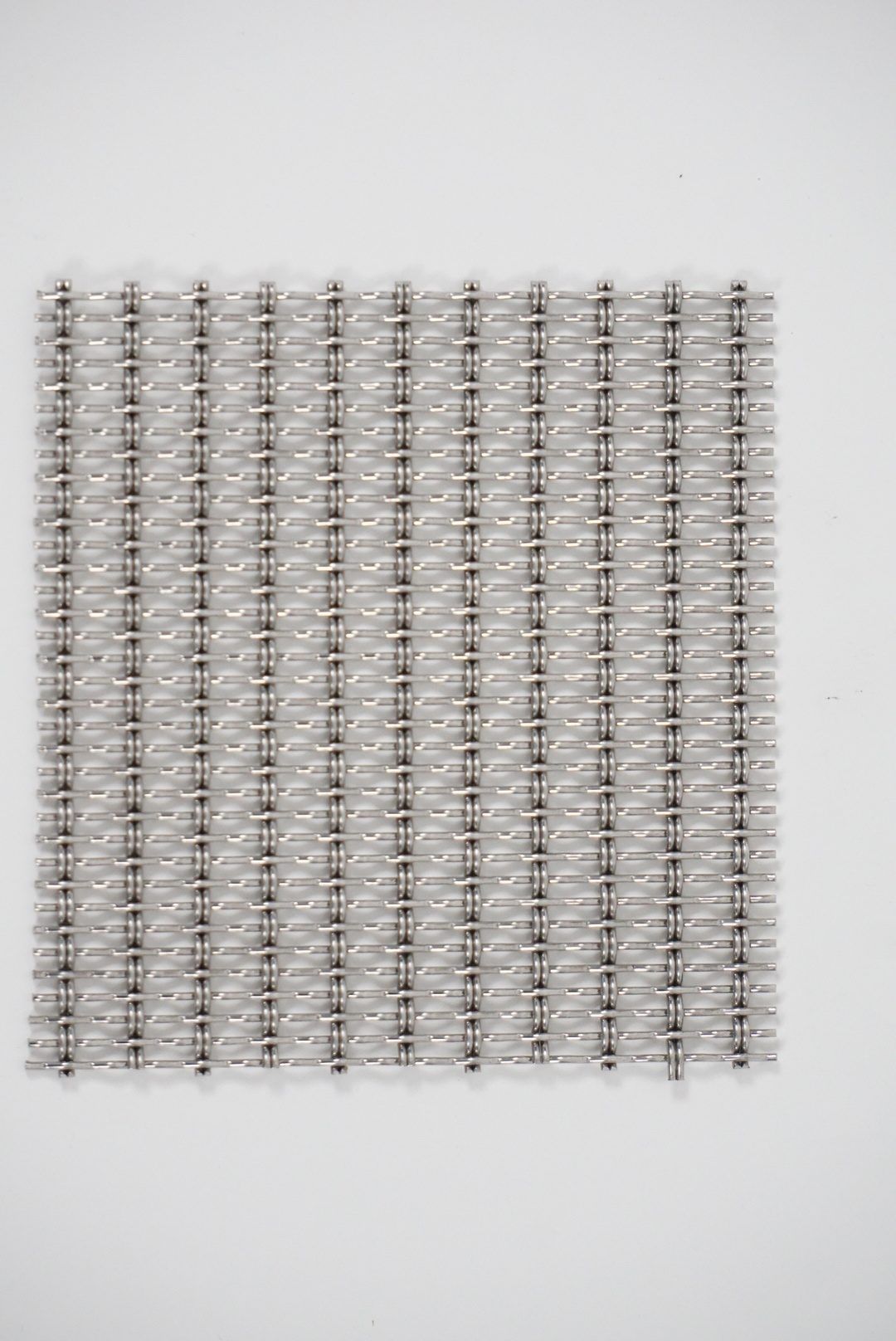

Rectangular weaving

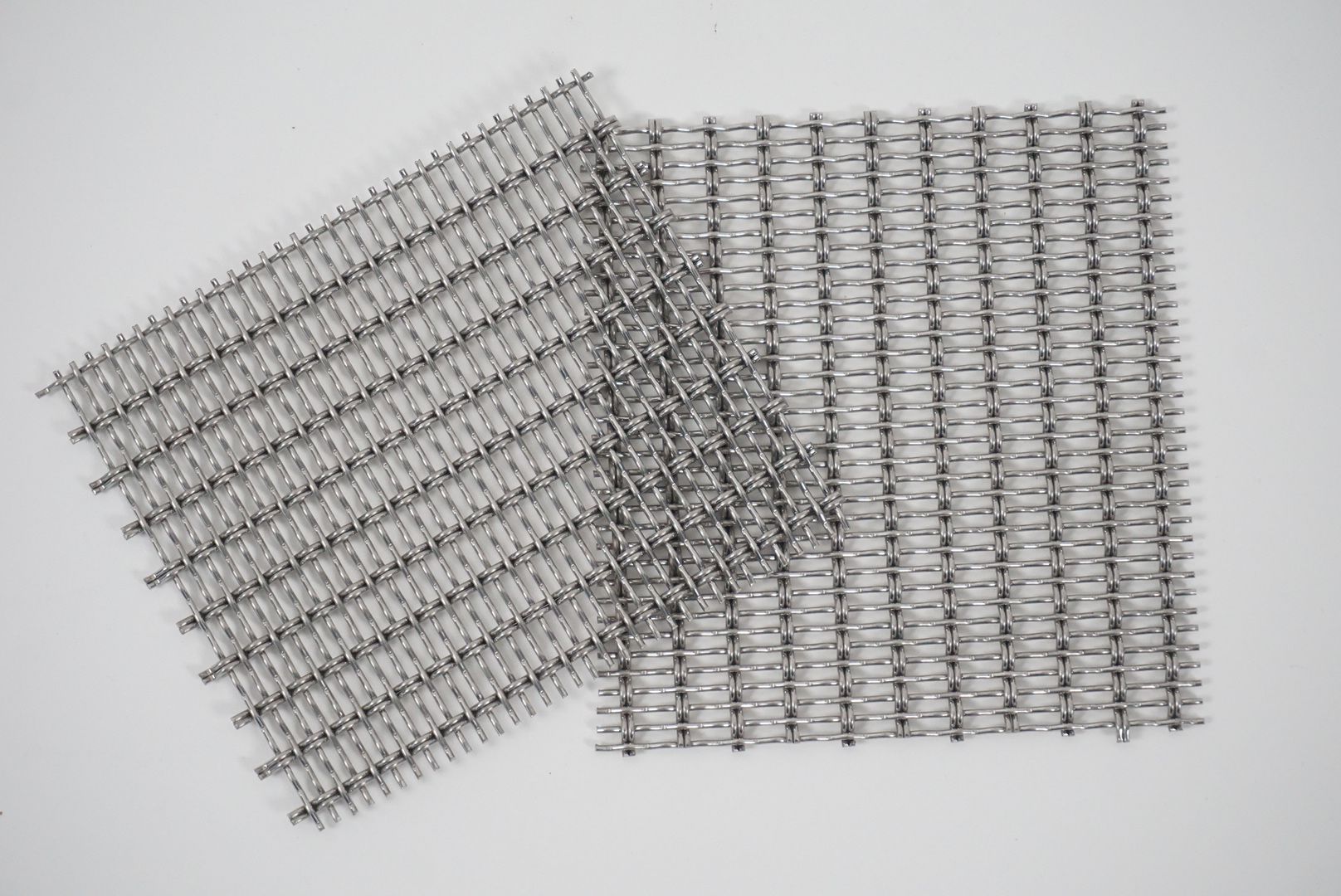

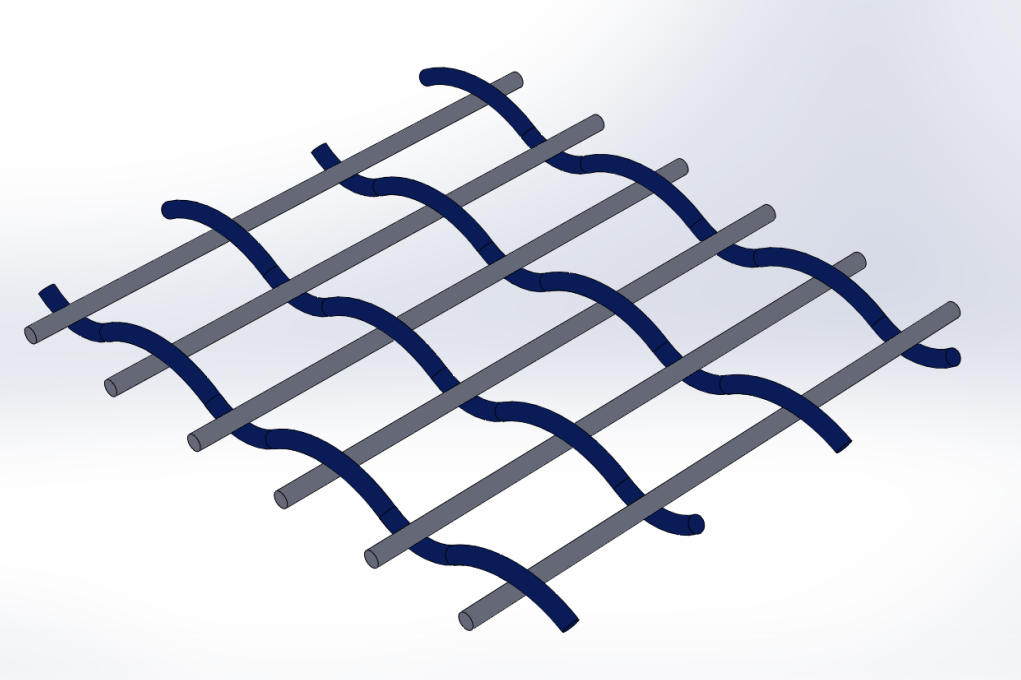

Rectangular weaving meets specific industrial needs and is frequently used in the screening of materials. There are many possibilities, but your dimensional characteristics will dictate whether you choose a mesh or a grating with preformed wires (ISO 14315 and ISO 4783-3).

Mesh and crimping weaving can be sold in rolls of any width, in panels of any geometric shape and transformed into finished products (panels with hooks, frames, cylinders, adv.) of any size.

The following information is needed to specify your mesh and determine its price:

- Raw material,

- Stainless steel Aisi 304, 304 L, 316, 316 L, 316 TI

- Stainless steel, magnetisable (430 adv.), refractory (321 adv.), super duplex (318 LN), adv.

- Annealed or high strength steel

- Galvanised steel

- Nickel, brass, copper, gold, titanium, adv.

- Weft or roll width: from a few mm up to 3 meters

- Warp or length of the roller: from a few metres to several hundred

- Mesh size or nominal opening, i.e., the distance between the 2 wires, in warp and weft: from 40µ to several mm

- Wire diameter: from 40µ to several mm, which may differ from warp to weft

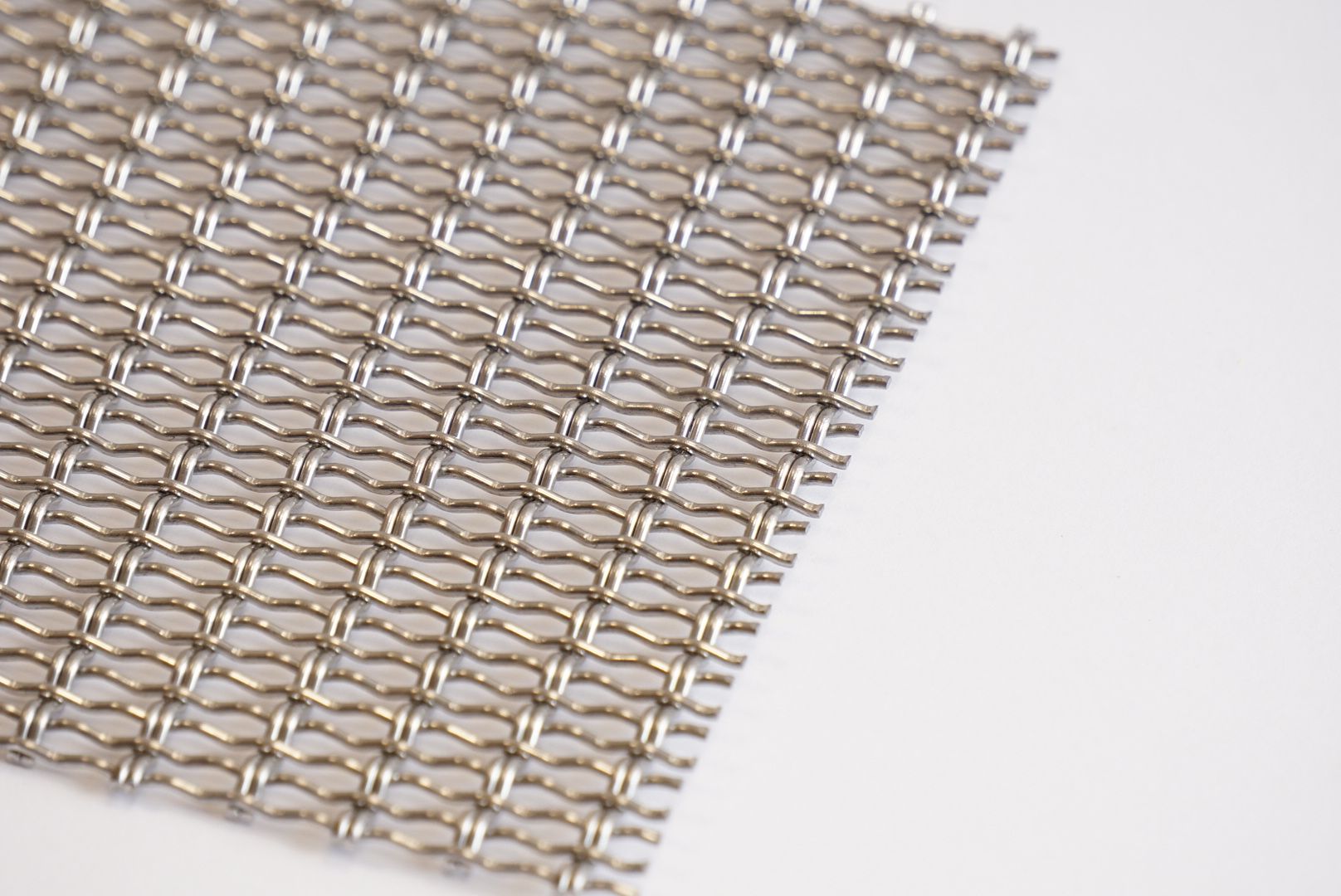

- Corrugation type, single / double / multiple in warp and/or weft

- Surface appearance, flat or corrugated

- Anchoring required to prevent mesh deformation

- Heat treatment (hyperquenching, adv.)

- Expected finish (degreasing, packaging, adv.)

You may have additional information to specify your mesh:

- Mesh is a common feature in Anglo-Saxon companies. To define your mesh, it must come with either the mesh size or the thread diameter.

- The Nr (number) is a common feature in French and Italian companies. To define your mesh, it must come with either the mesh size or the thread diameter.

- The percentage of open area or the “transparency” which characterises the productivity of your mesh. To define your mesh, it must be accompanied by the desired mesh.

- The Pitch, which corresponds to the mesh + a wire Ø.

We are ISO 9001 certified and meet the requirements (industrial mesh) and ISO 4783-2 (preferred combinations # and Ø) standards.

It is the guarantee to get a product of consistent quality, with all required certificates: dimensional, material, alimentarity, adv. SAULAS carry a large stock to ensure maximum availability. Our flexible, responsive organisation means we can quickly weave your mesh. (Subject to wire availability)

Wire mesh is our core business and has been manufactured since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. More than 8,000 customers in France and abroad have already placed their trust in us.