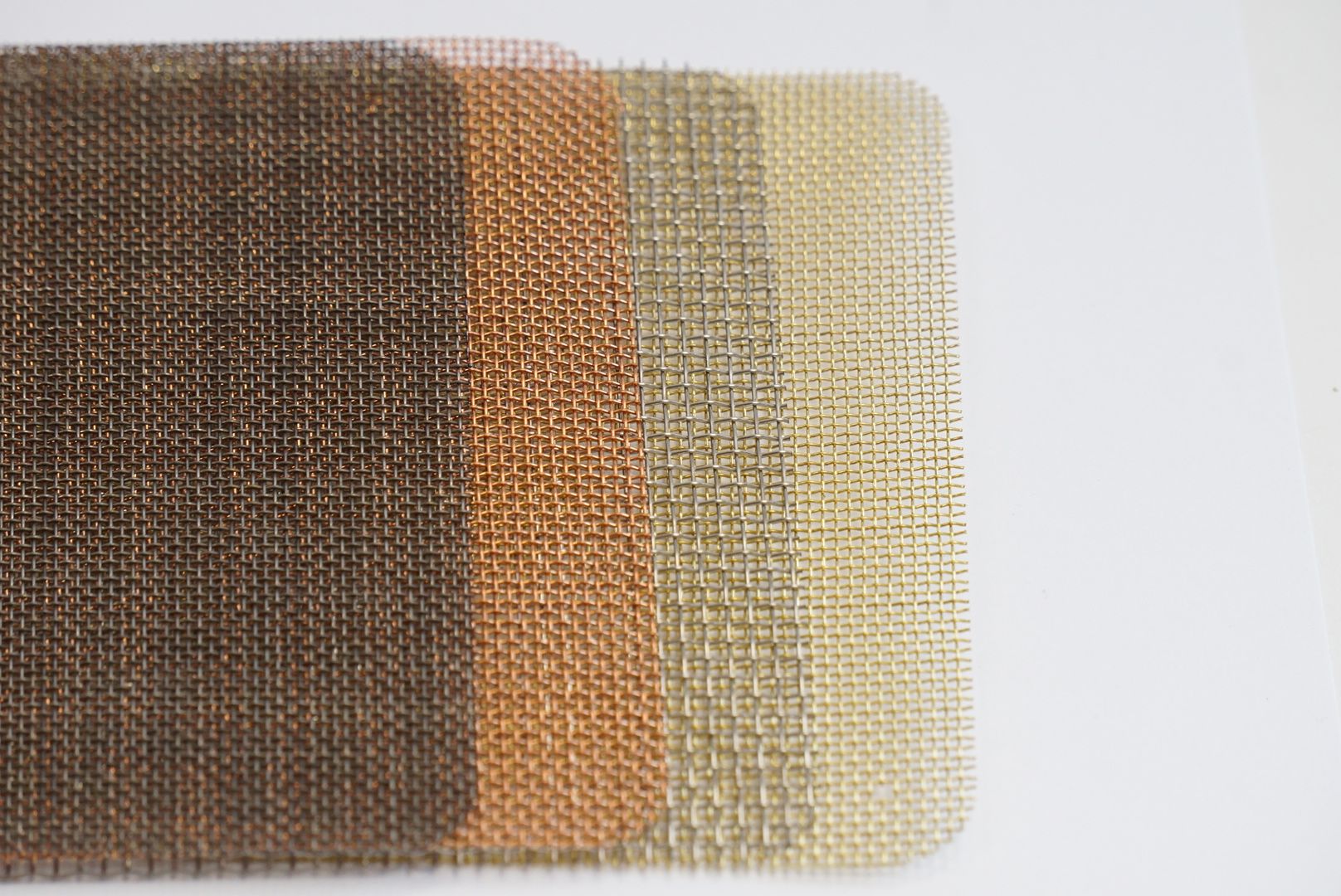

Non-ferrous meshes and grid

Meshes with non-ferrous wires are used in areas that require a high level of:

- Thermal and/or electrical conductivity

- Machinability and weldability

- Deformability

- Resistance to seawater corrosion

The most common materials are brass, bronze, beryllium copper, copper, nickel silver, cupro-nickel, nickel, aluminium and titanium.

Your choice will be based on their mechanical, chemical and economic characteristics.

These wires can be woven in plain, twilled or dutch weave. The choice will depend on your need for filtration threshold, resistance, deformability, ….

Copper or brass grid is commonly used to renovate historic monuments, particularly to protect stained glass windows.

They are knitted from annealed wire and generally feature a simple twist to join the wires, giving them great flexibility. Mesh sizes range from 3 to 100 mm, with wire diameters from 1 to 5 mm. These gratings are made to order.

Mesh can be sold in rolls of any width, in panels of any geometric shape and transformed into finished products (filter, frame, cartridge, cone, basket, adv.) of any size, in combination with support materials such as perforated plates, for example.

In addition to the dimensions and quantities of your product, the following information is needed to specify your mesh and determine its price:

- Raw material,

- Weft or width of the roll, from a few mm up to 3 meters

- Warp or length of the roller, from a few meters to several hundred meters

- Mesh size or nominal aperture, from a few µ to several mm

- Wire diameter, from a few µ to several mm

- Surface treatment (calendering, adv.)

- Expected finish (degreasing, marking, adv.)

- Packaging

You may have additional information to specify your mesh:

- Mesh is a common feature in Anglo-Saxon companies. To define your mesh, it must come with by either the mesh size or the thread diameter.

- Nr (number) is a common feature in French and Italian companies. To define your mesh, it must come with either the mesh size or the thread diameter.

- Percentage of open area or the “transparency” which characterises the productivity of your mesh. To define your mesh, it must be accompanied by the required mesh.

- Pitch, which corresponds to the mesh +wire Ø.

We are ISO 9001 certified and meet the requirements of ISO 9044 standard (industrial mesh).

It is the guarantee to get a product of consistent quality, with all required certificates: dimensional, material, alimentarity, adv…

SAULAS stocks most popular meshes. Generally, these materials will require a specific weave. Depending on the wire availability, our flexible and responsive organisation will ensure a rapid turnaround.

Mesh is our core business and has been made since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. More than 8,000 customers in France and abroad have already placed their trust in us.