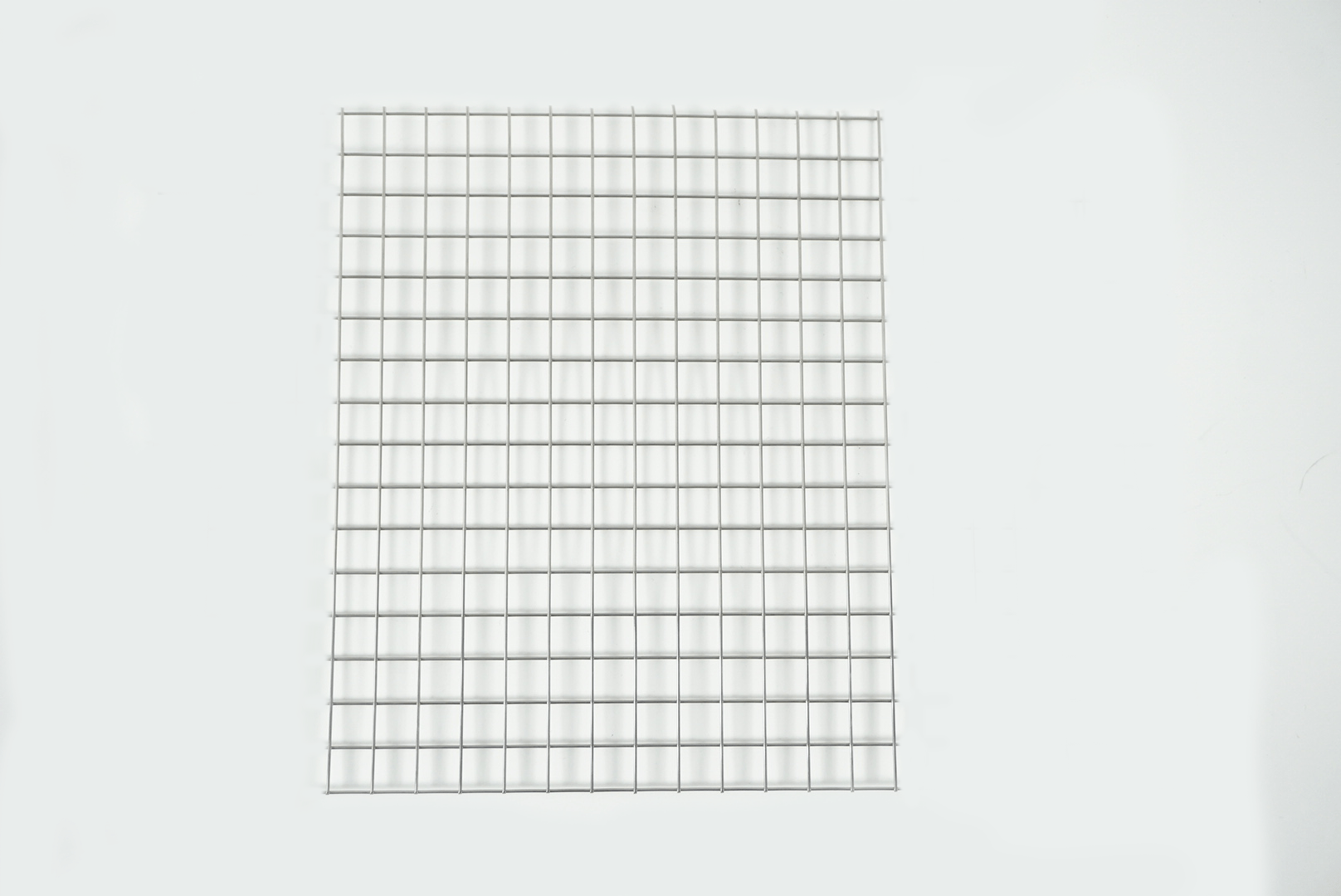

Welded wire mesh

SAULAS welded mesh is used in many applications as protection, separation, reinforcement or support, often in conjunction with filter media. In this case, we often find it in the air filtration sector.

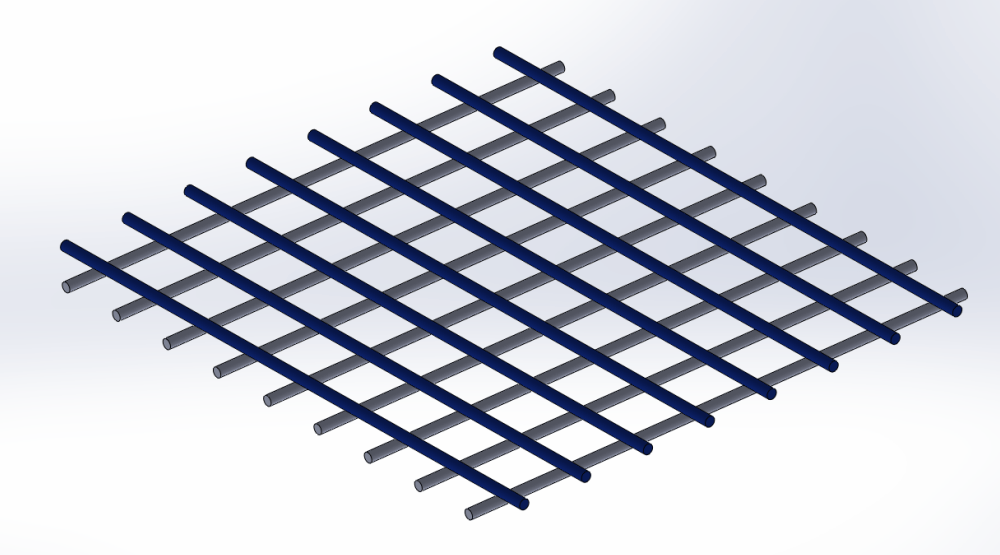

Each wire crossing is electrically soldered. This makes possible to have very large stitches vs a thin wire Ø, while maintaining very good hold. It will therefore be lighter, more flexible and cheaper than crimping weaving, but less resistant at comparable mesh size.

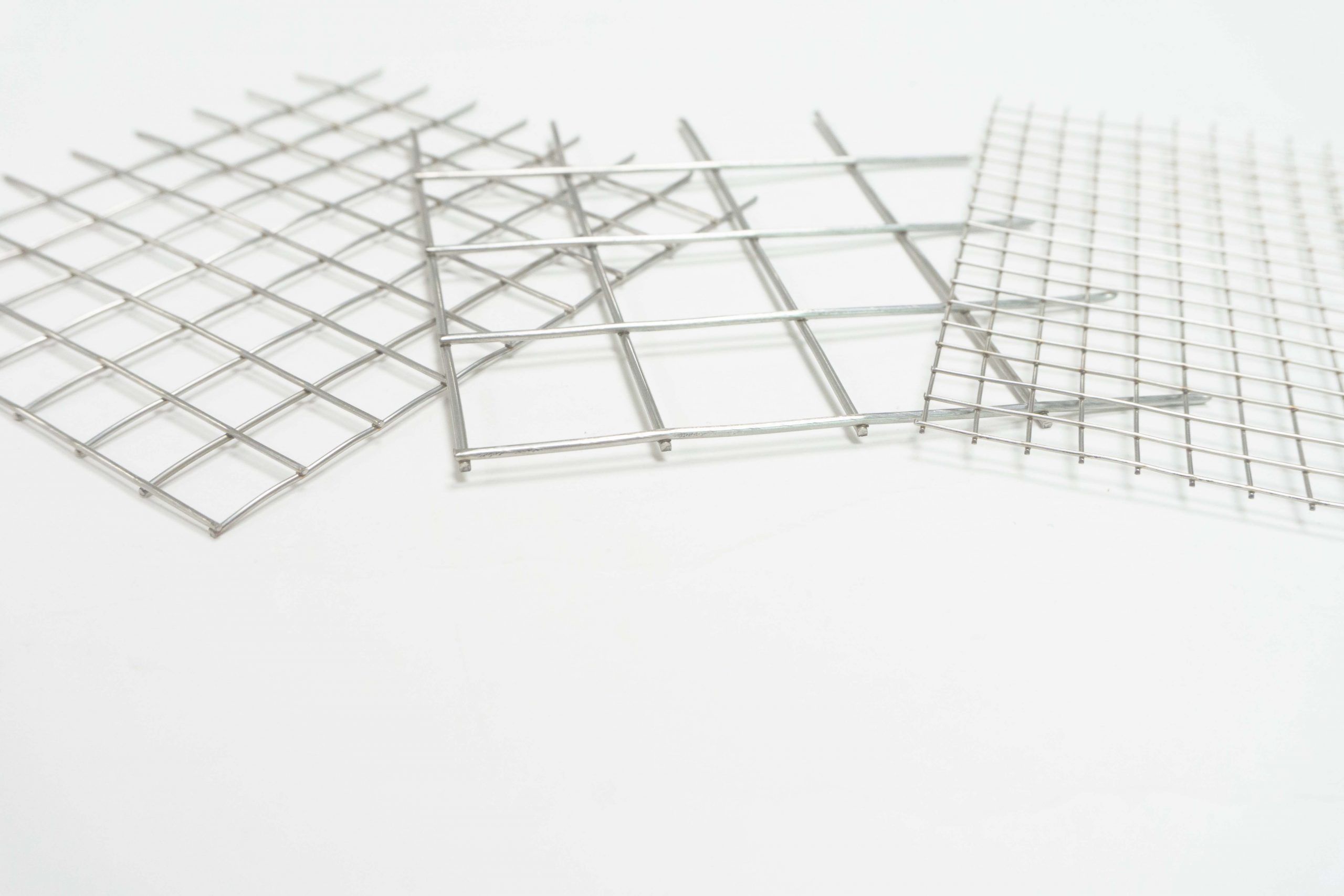

As with mesh, there is a wide choice of sizes. SAULAS stocks the most used references. We sell them in rolls, in panels of any geometric shape or transformed into finished products (filters, baskets, cylinders, adv.) of any size.

In addition to the dimensions and quantities of your product, the following information is needed to specify your mesh and determine its price:

- Raw material, for welded mesh, is available in

- Stainless steel Aisi 304, 304 L, 316, 316 L

- Galvanised steel, corrosion-resistant protection by galvanising wires, after or before welding

- Annealed steel (without protective treatment)

- Pitch, which corresponds to one mesh + one wire diameter or to the distance between wires

- Thread wire diameter

- Side finishing of the roll or panel with or without spikes

- In the case of a roll, we can wound on a cardboard chuck

- Required surface treatment and finish (degreasing, adv.)

- Required certificates (material, dimensions, adv.)

- Packaging

Welded mesh specifications are often given in fractions of an inch. Given that oneinch equals 25.4 mm, we frequently find following dimensions:

- 1” or 25.4 mm pitch, available with wire diameters from 1.6 to 1.0 mm

- ½ ” or 12.7 mm pitch, available with wire diameters from 1.6 to 0.63 mm

- ¼ ” or 6.3 mm pitch, available with wire diameters from 1.0 to 0.63 mm

Manufacture of welded mesh with other dimensional specifications will depend on the combinations proposed by ISO 4783/3 standard, and on the required quantities and lead times. Our pitch capabilities range from a 4 mm to 100 mm!

As with crimping weaving, ISO 14315 standard defines the average manufacturing tolerance (Ys) on the mesh opening. It varies from 3.5 to 5.0% depending on the opening gauge.

SAULAS is ISO 9001 certified and regularly invests in production tools to provide you with the best possible service rate. We have been based near Troyes (FR) since 1960 and are organised to respond quickly to your needs. More than 8,000 customers in France and abroad have already placed their trust in us.