Granulator screens

Granulator screens are commonly used in the pharmaceutical, chemical and food industries to deagglomerate, calibrate and homogenise powders and granules. We also find them in other industry sectors, such as metallurgy, for the same needs.

Several major manufacturers are active in this market. Frewitt®, Alexanderwerk®, Erweka®, Fitzmill® and Sahut Conreur® are the best known. They offer technologies that may be different, but all have in common the use of grids or perforated plates in several forms.

80 years ago, SAULAS began manufacturing stainless steel laboratory sieves with wire mesh and perforated sheets. We integrate all the manufacturing stages, including the weaving of the finest meshes. Our measuring instruments are widely recognised for their quality and reliability and can be found in most industries and laboratories.

So it was only natural, more than 50 years ago, that we offered our customers our expertise in the production of granulation grids, perfectly adapted to their machinery, with the same concern for quality. Over the years, we have followed the development of their production tools and extended our range.

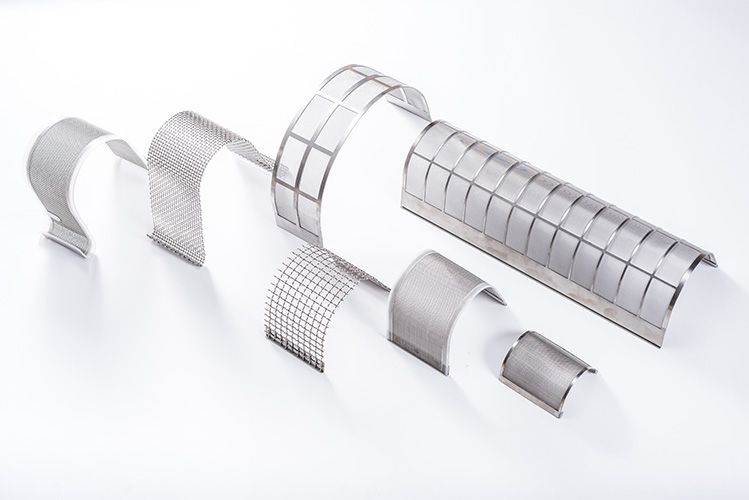

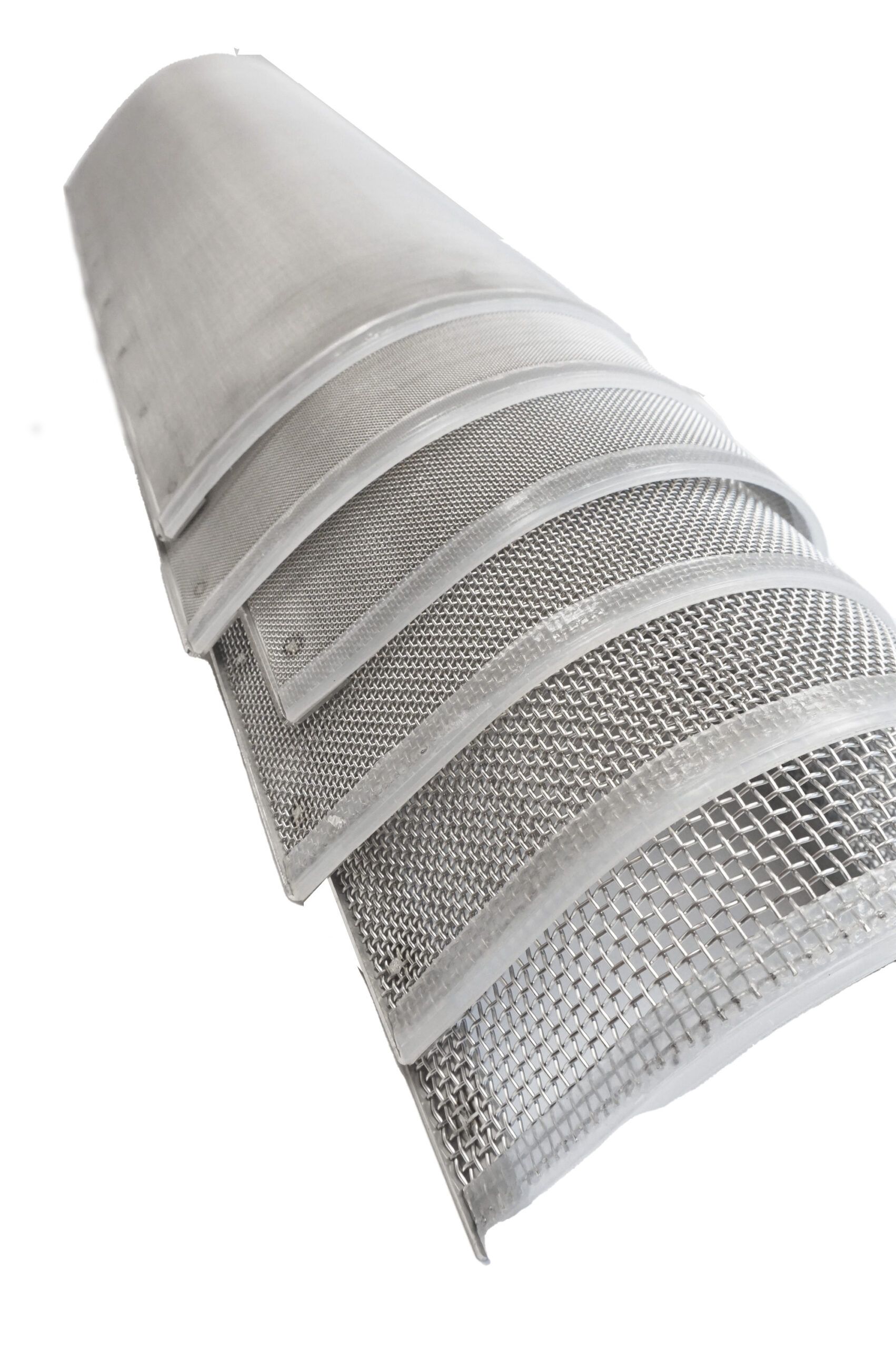

At the present time we propose:

- Stainless steel granulator screens, round wires, square wires, compatible with any machine model on the market, with or without cradle, any finishes

- Granulation cones or cylinders, in stainless steel perforated plates, round, square or spherical holes (grater), also compatible with existing machines

- Certificates of conformity, of materials 3.1, of alimentarity and measurement

- Dimensional inspection of your grids, cones and cylinders, thanks to our dimensional laboratory and its optical equipment, COFRAC accredited for laboratory sieves

Our modern machinery and extensive stock enable us to respond as quickly as possible. We regularly handle your “emergencies” with a 24/48-hours solution.

Our meshes, grid and sheets comply with ISO 9044, ISO 3310, ISO 7806 and ISO 14315 standards.

Our field sales team will come and meet you to take the dimensions and characteristics needed to manufacture your product. This will enable our design office to draw up a detailed drawing for you.