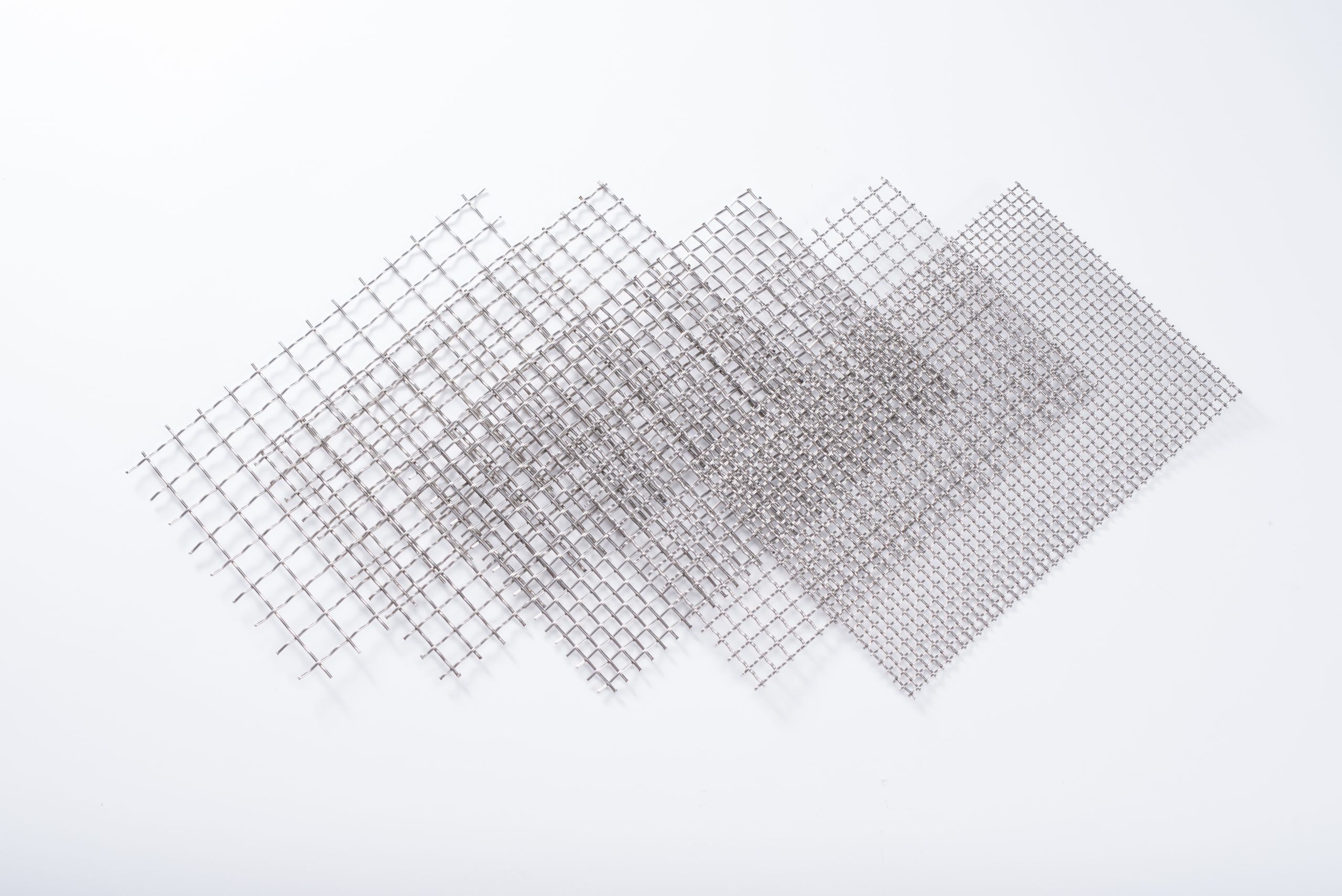

Crimping weaving

SAULAS crimping weaving is widely used when you need to screen any kind of ore, for example in the chemical or building materials industries. We generally find it in the form of panels with hooks, stretched across screens of all brands. But they are also frequently used in many applications as protection, separation, reinforcement or support (in addition to filter media).

Crimping weaving differs from mesh in that it uses hardened steel wire, often pre-formed before weaving. This initial deformation ensures that the wires are well anchored to each other and leaves open the possibility of having either a very large ratio between the mesh and the wire diameter, or, to the contrary, a very small ratio. In any case, these are highly resistant products designed to withstand heavy mechanical stress and wear.

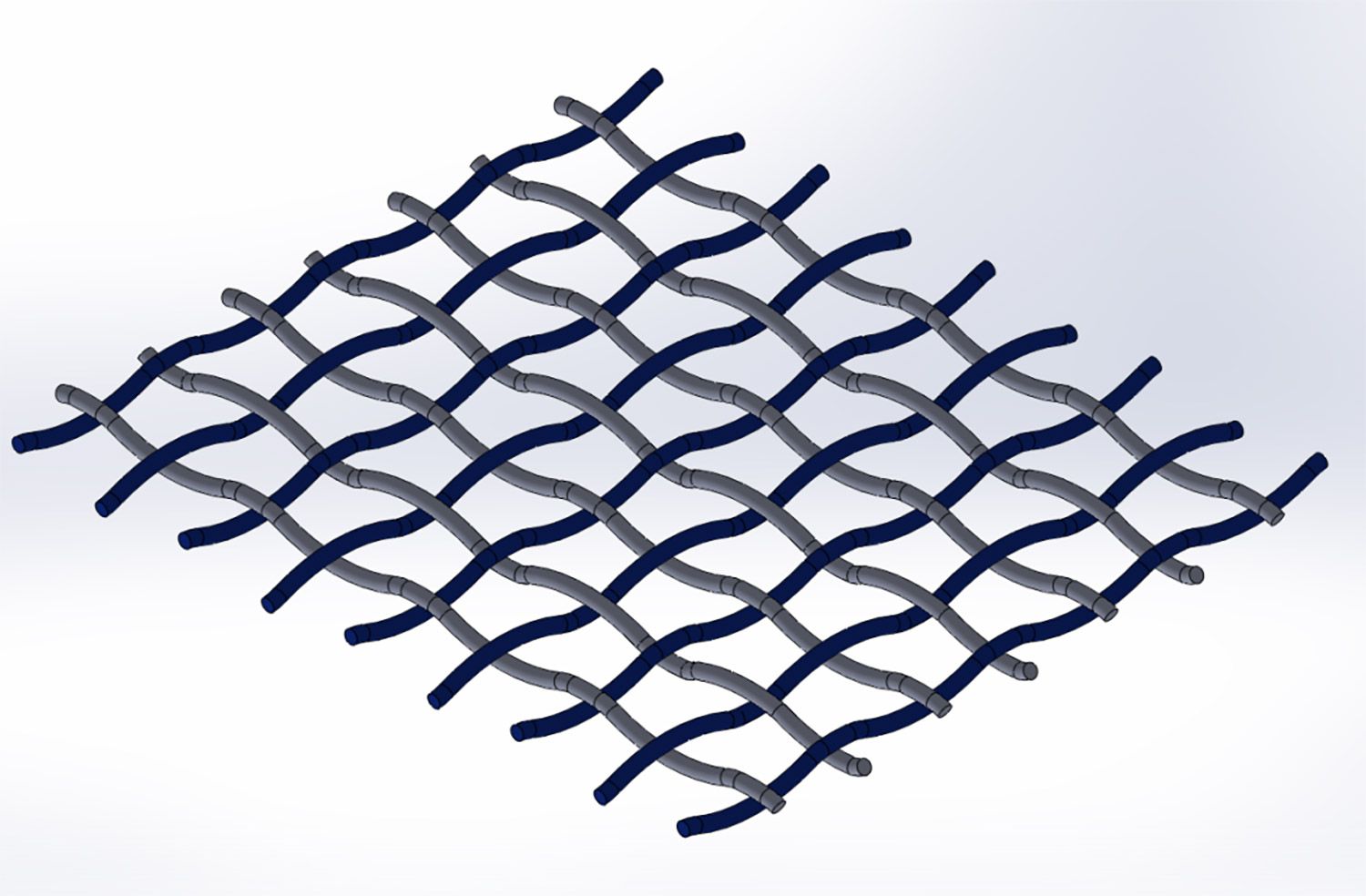

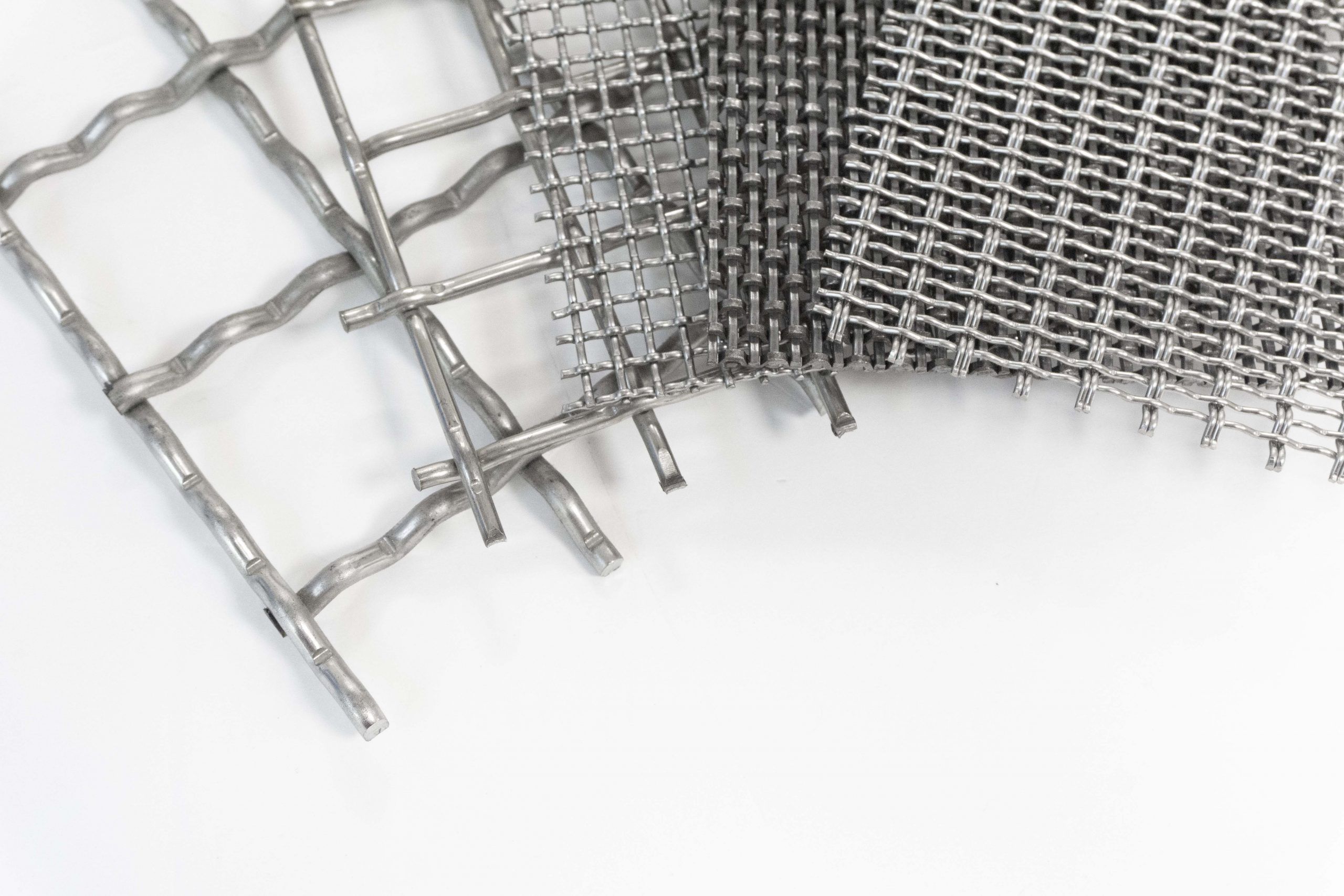

ISO 4783/3 standard defines 4 types of crimping weaving

- Type B, one weft crimp and double or triple warp crimp

- Type C, double or multiple weft and warp corrugations

- Type D, double-anchored weft and warp corrugation

- Type E, asymmetrical corrugation, giving a flat surface on one side

These crimping weaving are available in rolls or panels of any size and geometric shapes, but the SAULAS machine stock and our experience allow us to transform them, according to your drawings, with any desired finish (inverted B hooks with Morgensen® joint and striking strips, for example, for a panel with hooks with longitudinal tension, adv.).

In addition to the dimensions of your product and the quantities required, the following information is needed to specify your crimping weaving and determine its price:

- Raw material,

- Stainless steel Aisi 304, 304 L, 316, 316 L, 316 TI

- Stainless steel, magnetisable (430 adv.), refractory (321 adv.), super duplex (318 LN), adv.

- High-strength steel

- Galvanised steel

- Mesh, with, in the case of rectangular meshes, specify the rectangle direction

- Crimping weaving type, with the possibility of using a specific anchoring system (double wire)

- Wire diameter

- Surface treatment and finishes required (degreasing, adv.)

- Required certificates (material, measurement, adv.)

- Packaging

Preferred combinations of mesh and wire diameters are listed in standard ISO 4783/3 standard. Our possibilities are huge (mesh from 0.1 to 125 mm – wire from 0.1 to 25 mm) and are limited only by the capacity of our tools.

As with welded mesh, ISO 14315 standard defines the average manufacturing tolerance (Ys) on the mesh opening. It varies from 2.5 to 5.0% depending on the opening range.

SAULAS carries stock of the most commonly used crimping weaving. Depending on wire availability, our flexible and responsive organisation will ensure a quick turnaround.

SAULAS is ISO 9001 certified and regularly invests in production tools to provide you with the best possible service rate. We have been based near Troyes (FR) since 1960 and are organised to respond quickly to your needs. More than 8,000 customers in France and abroad have already placed their trust in us.