Porous metal

Porous metal is used for:

- Microfiltration and ultrafiltration of liquid or gaseous fluids (candles, discs, adv.)

- Fluid separation

- Flow control and pressure drop (silencer, protection)

- Anti-humidity (drying fluids and preventing corrosion)

- Fluidisation and aeration (powders)

- Backfire prevention

It is frequently used in the chemical industry (purification, fluidisation, drying, adv.), the food industry (gasification, ultrafiltration, adv.), appliances and machinery (gas, adv.), adv.

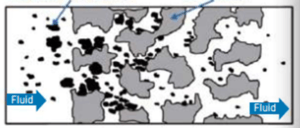

It has a filtration efficiency of 0.2 µ to 270 µ, evenly distributed throughout the filter. The fluid’s complex path ensures deep filtration.

Internal structure and materials used ensure good resistance to high temperatures, pressure and chemical attack (stainless steel).

These filters have a long service life and can be reused after backwashing.

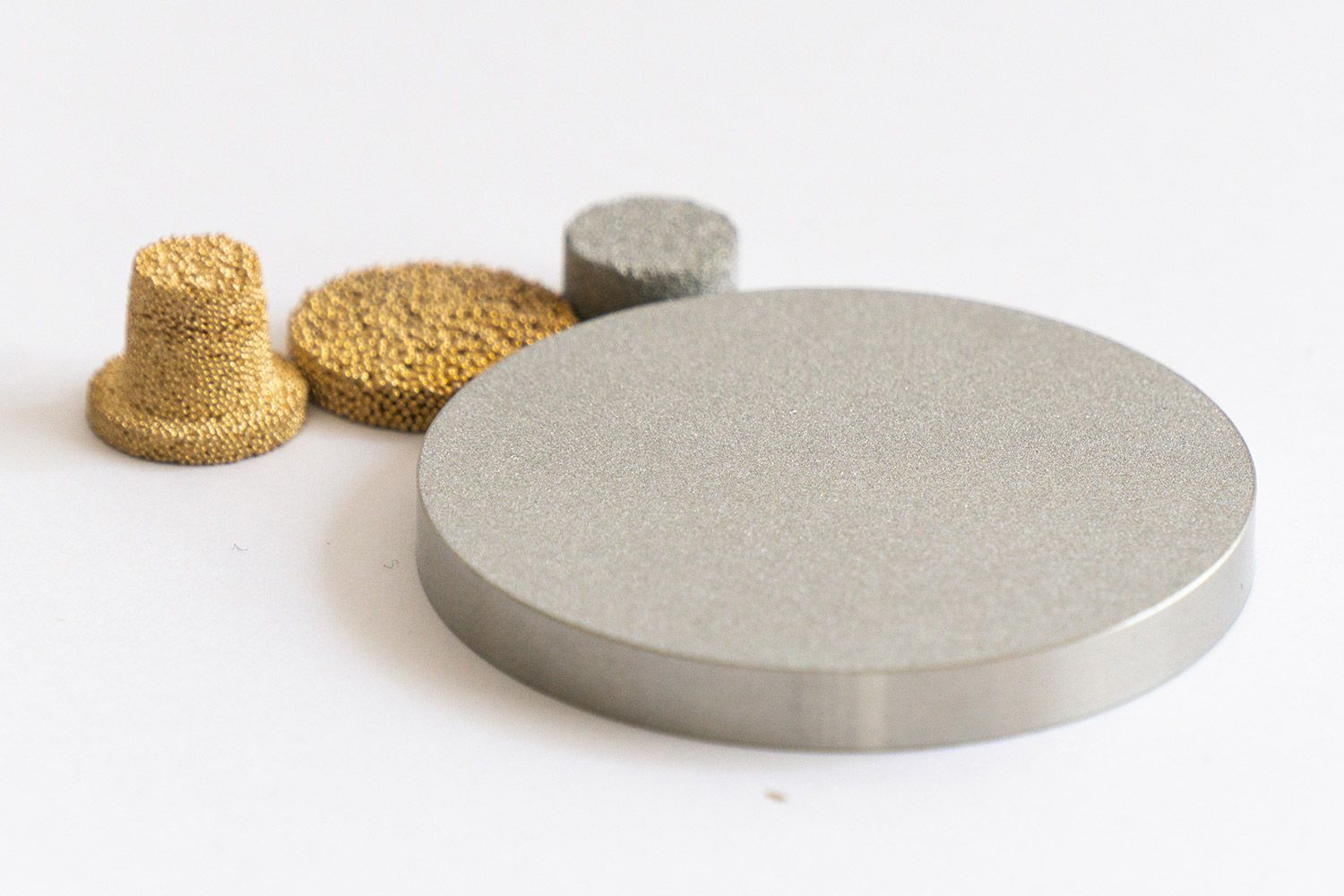

Filters are manufactured using powder technology. With different grain sizes, in stainless steel or bronze, they are more or less compacted in a mould depending on the porosity required. The particles are welded together by sintering, a process in which the temperature and pressure are raised for a given period of time in a controlled atmosphere.

The resulting product is extremely rigid and easy to work on (cutting, welding, machining, adv.), without the need for additional support, such as perforated sheeting.

The following information is needed to specify your mesh and determine its price:

- Raw material,

- Stainless steel Aisi 316 L (std), 304L

- Monel or Inconel

- Hastelloy-type superalloy

- Bronze

- Porosity, from 0.2 µ in stainless steel and 0.7 µ in bronze

- Filtration surface

- Dimensions of the finished product

We are ISO 9001 certified and offer products that meet the requirements of current standards. It is the guarantee to get a product of consistent quality, with all required certificates: measurement, material, alimentarity, ….