Treated and coated meshes

For some specific uses, and in order to give them additional properties, it is necessary to carry out treatments on the meshes after weaving: degreasing, pickling, passivation, heat treatments, surface coating, adv.

SAULAS’ knowledge and experience enable us to provide you with all needed advice and to implement most post-treatments in-house or through a network of partners.

Degreasing: wire drawing and weaving operations usually require the use of soaps or oils that need to be removed for pharmaceutical or food applications.

We are able to adapt our degreasing process, based on an alkaline degreaser, rinsing and drying, to the specific needs of our customers.

Passivation stripping (stainless steel): Since welding operations can alter the passive layer that protects stainless steels against corrosion, we use pickling and passivation operations to restore these properties.

Our processes can also be validated by carrying out corrosion tests and issuing the corresponding certificates.

Heat treatment: steels and stainless steels offer numerous possibilities for adapting their mechanical characteristics, depending on their metallurgical state. Hyper-quench heat treatment processes, for example, have been developed to meet the need for deep drawing.

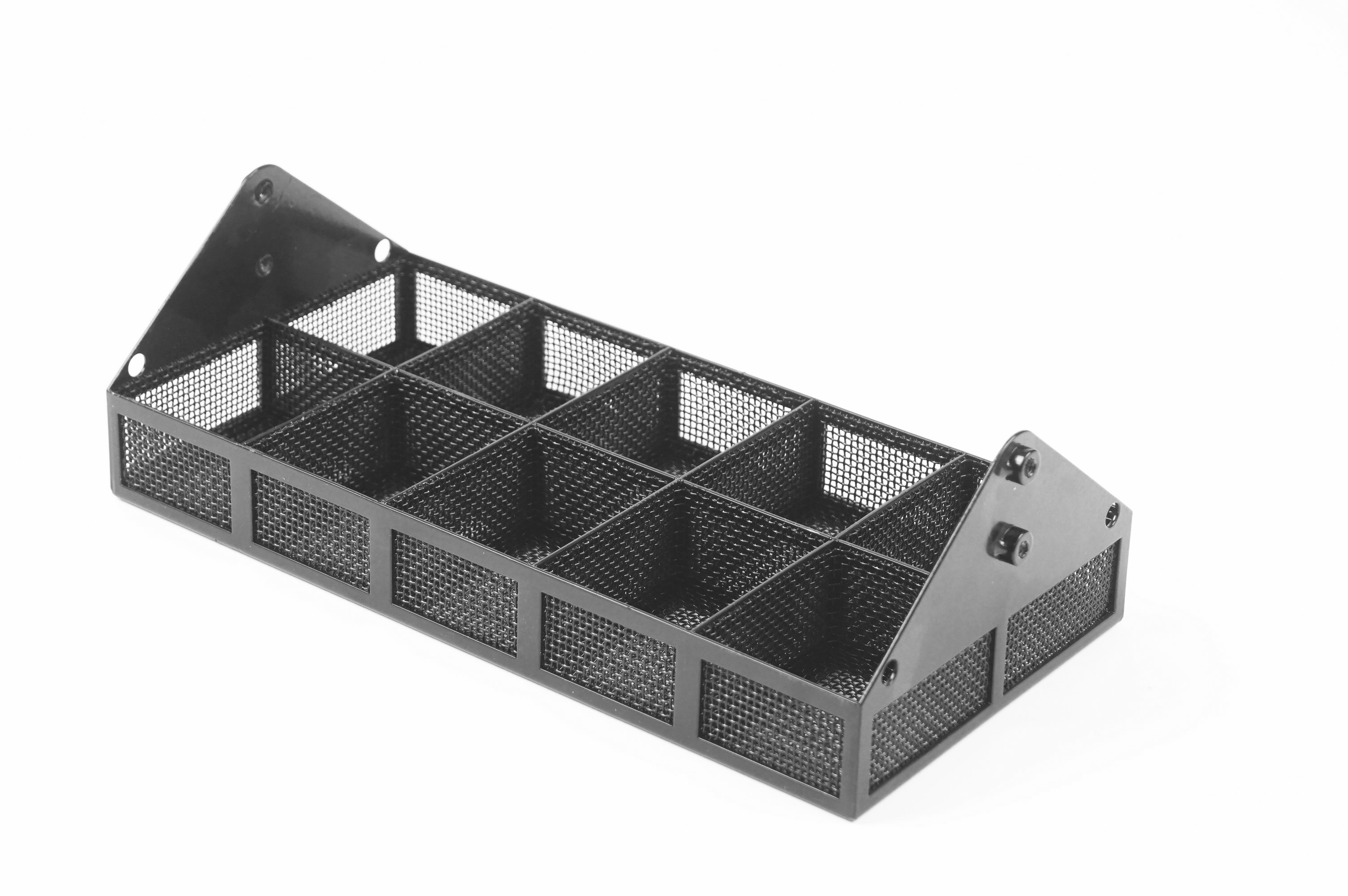

Coating: Whether you want to add colour (epoxy paint, ink), limit abrasion or adhesion (PTFE), or provide protection (rilsan coating), we can help you develop suitable coating processes.

Our design office is able to support you to develop processes that guarantee desired properties.