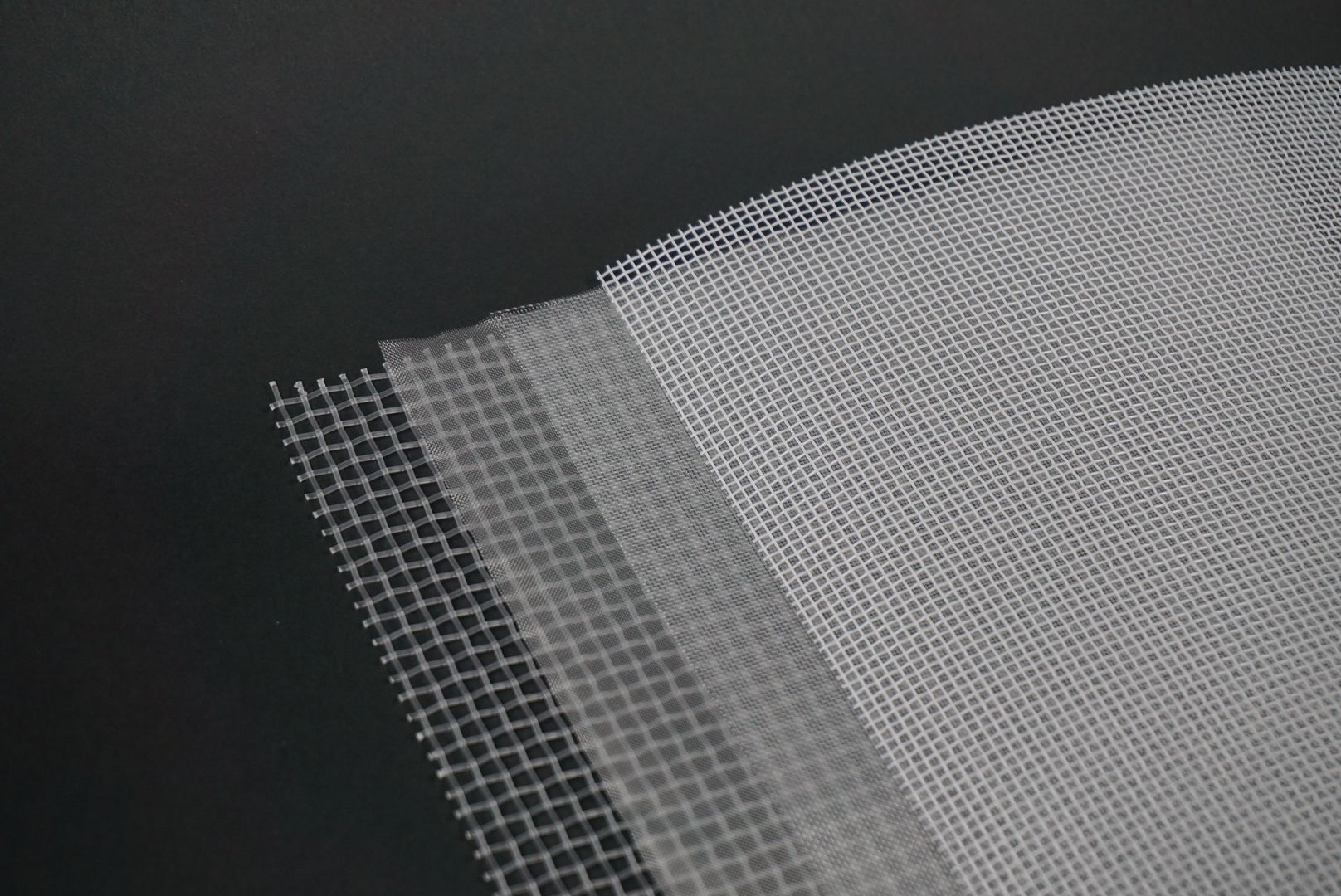

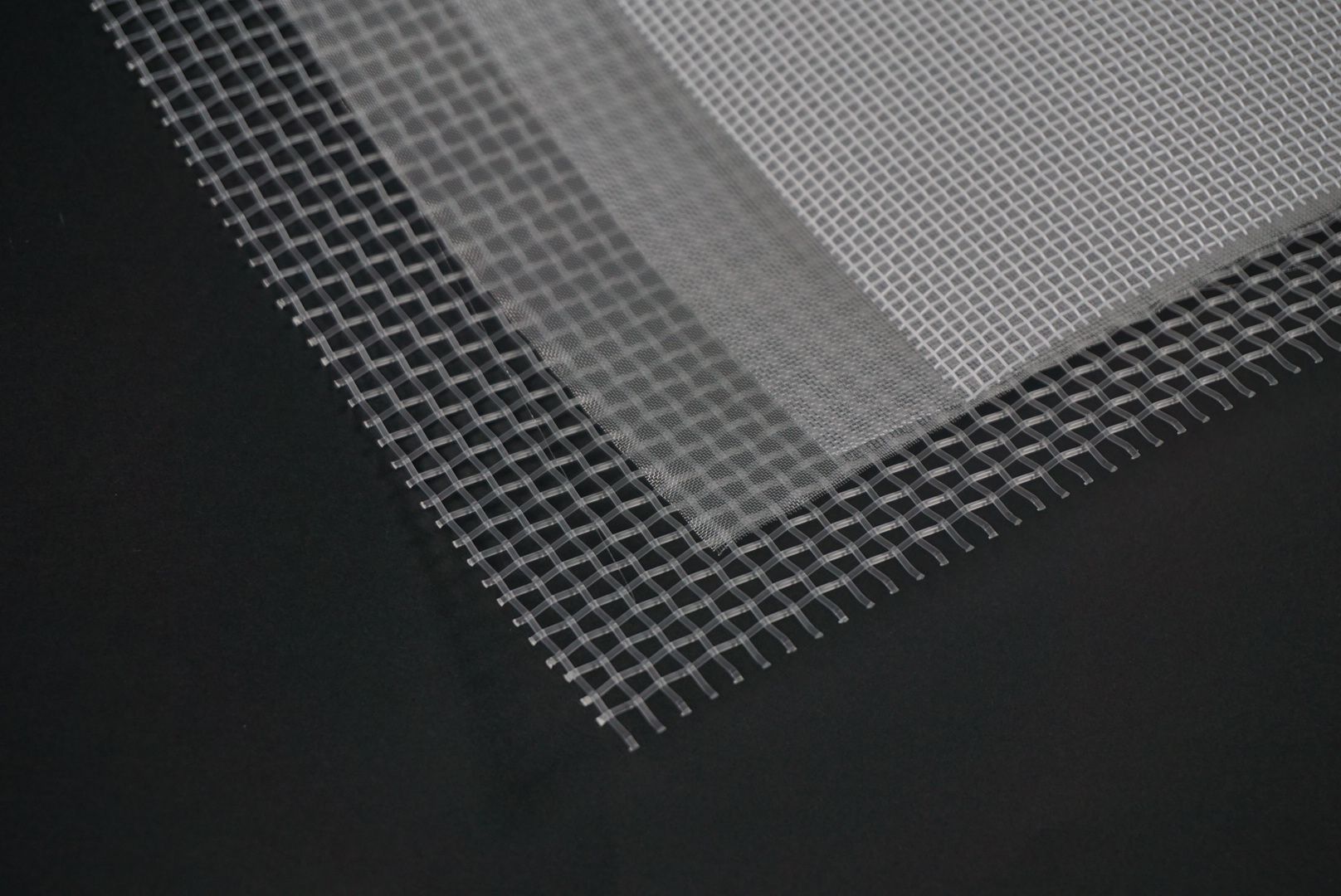

Synthetic meshes

Synthetic meshes are widely used in the food and chemical industries. They can be found in various forms for draining/spinning, filtration (press filter, rotary, disc, belt, bag, candle, adv.), or sieving of solid, liquid or gaseous products.

Materials generally used are:

- Polyamide, PA 6 or 6.6 (nylon) or 11 (rilsan) or 12

- Polyester, PES (Tergal, Dacron, Mylar, adv.)

- Polypropylene, PP

- Polyethylene, PE

They are generally highly resistant to acid and/or alkaline media at maximum temperatures of between 90 and 160°C / 194 and 320°F.

The choice will be based on their mechanical, chemical and economic characteristics.

They are woven with monofilaments, multifilaments, spun fibers, in several weaves, which will define a filtration threshold ranging from 0 to 5000 µ, resistance, ease of cleaning or deformability.

- Plain weave (1/1) mono or multi filament in PA, PES, PP or PE

- Twilled (2/1/2) mono or multi filament in PA, PES, PP

- Satin (or twilled, 4/1/4) mono filament in PA, PES, PP

- Chevron (or reverse twill) mono filament in PA, PES, PP

- Dutch weave, multi-filament in PET or PP

They are also available in non-woven. They are then called “non-woven “ or ” needle felt “ and produce thicker meshes with a very low filtration threshold, down to 1µ. They are used to filter liquids as well as air in dust removal activities, for example. They are made of Polyester (PES) or Polypropylene (PP).

All these meshes can be sold in rolls or as finished products. They are easy to cut, sew or glue and can be quickly shaped into any shape: pockets, handles, flat filters, sieve frames, adv.

In addition to the dimensions of your product and the quantities required, the following information is needed to specify it and determine its price, which will depend on the objective sought:

- Raw material,

- Width (or weft) of the roll, up to 2 meters

- Warp (or length) of the roll

- Selvedge finish

- Mesh size or nominal aperture, in µ

- Wire diameter, in µ or mm

- Weight per sqm

- Thickness

- The transparency, or percentage of open area (in %)

- Air permeability (in l/sqm/s)

- Fracture strength on test specimens (in N)

- Assembly type (sewing, welding, adv.)

- Marking

- Surface treatment (heat setting, calendering, adv.)

- Expected packaging (wrapping, adv.).

SAULAS is ISO 9001 certified and has a stock to ensure maximum availability. Our flexible, responsive organisation guarantees you short lead times. More than 8,000 customers in France and abroad have already placed their trust in us.