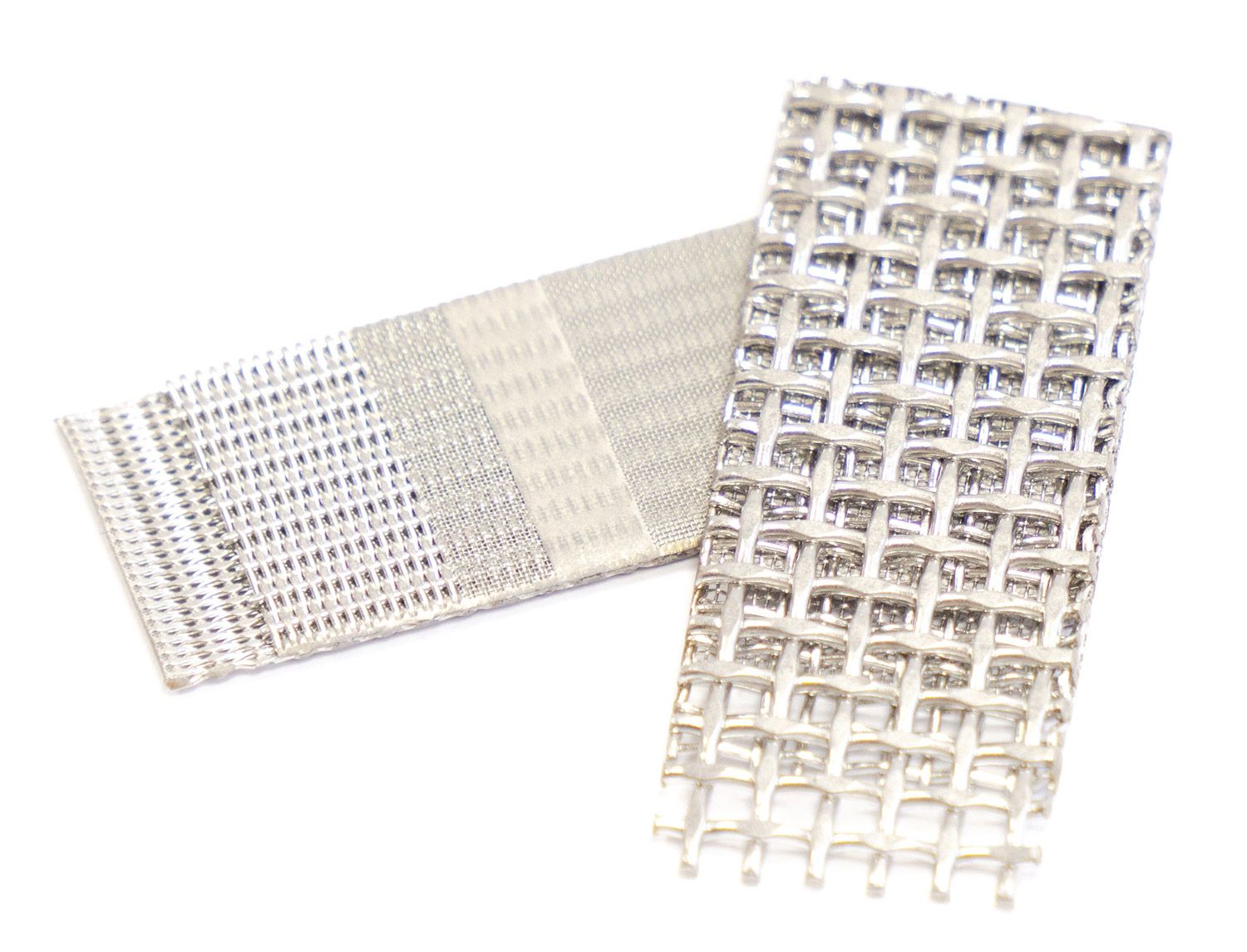

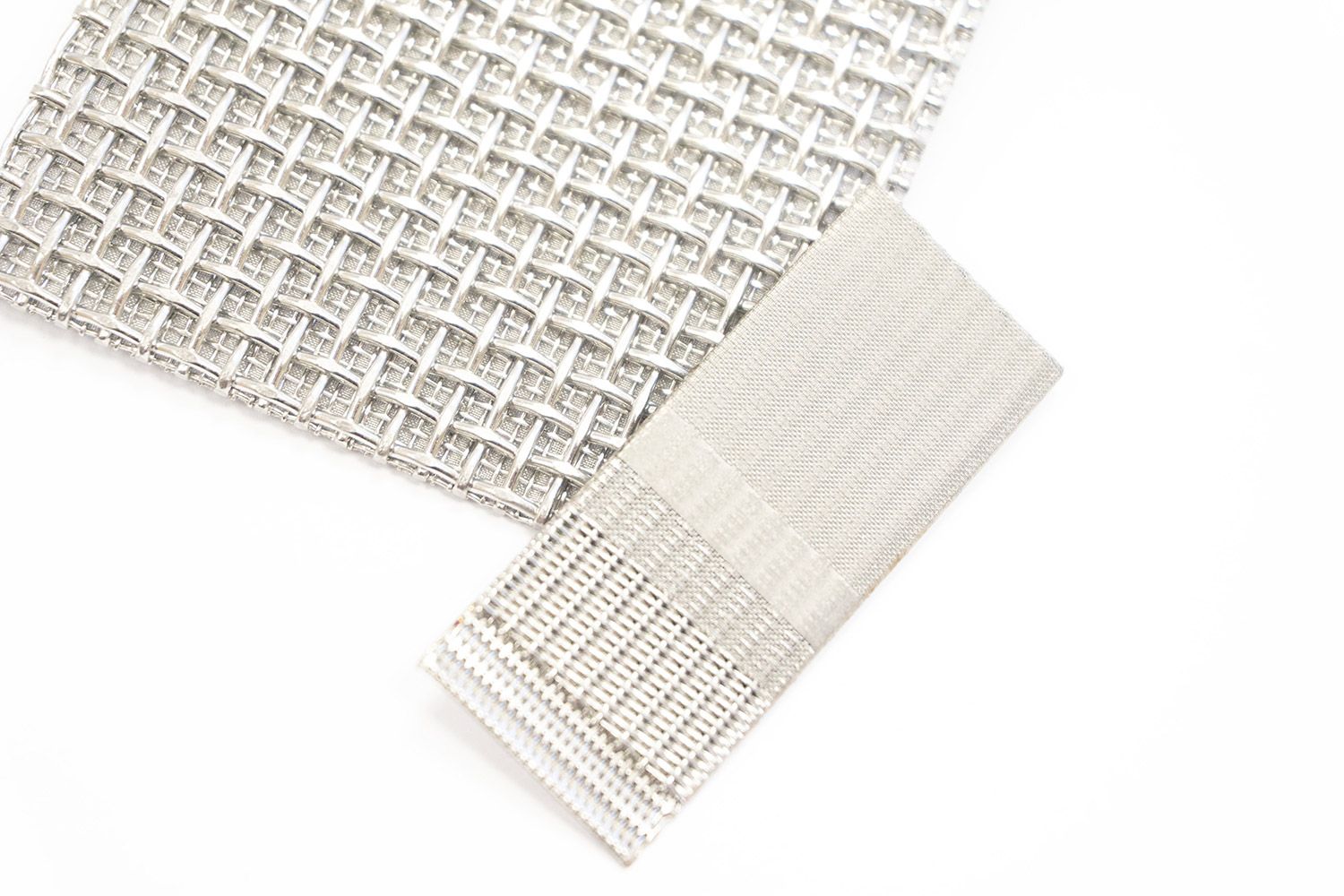

Sintered meshes

Because of the way is manufactured, this specific product is used for:

- Gases or viscous liquids filtration (cartridges, Nutsche®, discs, panels, adv.)

- Fluidisation, aeration

- Centrifuges

It is frequently used in chemical, petrochemical and pharmaceutical applications.

It is the stacking of several meshes of different sizes, assembled by sintering (pressure + temperature) and laminated, that gives the whole thing its rigidity and provides thin filtration with great resistance to operating pressure and cleaning.

The nominal filtration threshold starts at 1 µ.

This “cake” or “laminate” is generally made up of 3 to 5 meshes (2 to 8 are available).

- The first one is to protect the filter mesh.

- The second one determines the nominal filtration rating, dutch or thin twilled.

- The third one allows is for spreading.

- The following ones are used for support, usually strong crimping weaving or dutch.

This assembly is rigid and strong enough to be used without any additional support, such as perforated plates, for example.

These meshes can be sold as single panels (max. 1200×1200) or transformed into finished products (filters, candles, discs, cones, adv.). Our welding equipment can handle any size.

The following information is needed to specify your mesh and determine its price:

- Raw material,

- Stainless steel Aisi 304 L, 316 L, 316 TI

- Uranus B6 stainless steel

- Nickel-based Hastelloy superalloy

- …

- Nominal aperture, from 1µ

- Maximum mesh thickness

- Dimensions of the finished product

- Expected finish (degreasing, packaging, adv.)

We are ISO 9001-certified and offer mesh and crimping weaving that meets the requirements of current standards, ISO 9044, NFX 11-515 and ISO 14315. It is the guarantee to get a product of consistent quality, with all required certificates: measurement, material, alimentarity, adv. Wire mesh is our core business and has been manufactured since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. More than 8,000 customers in France and abroad have already placed their trust in us.