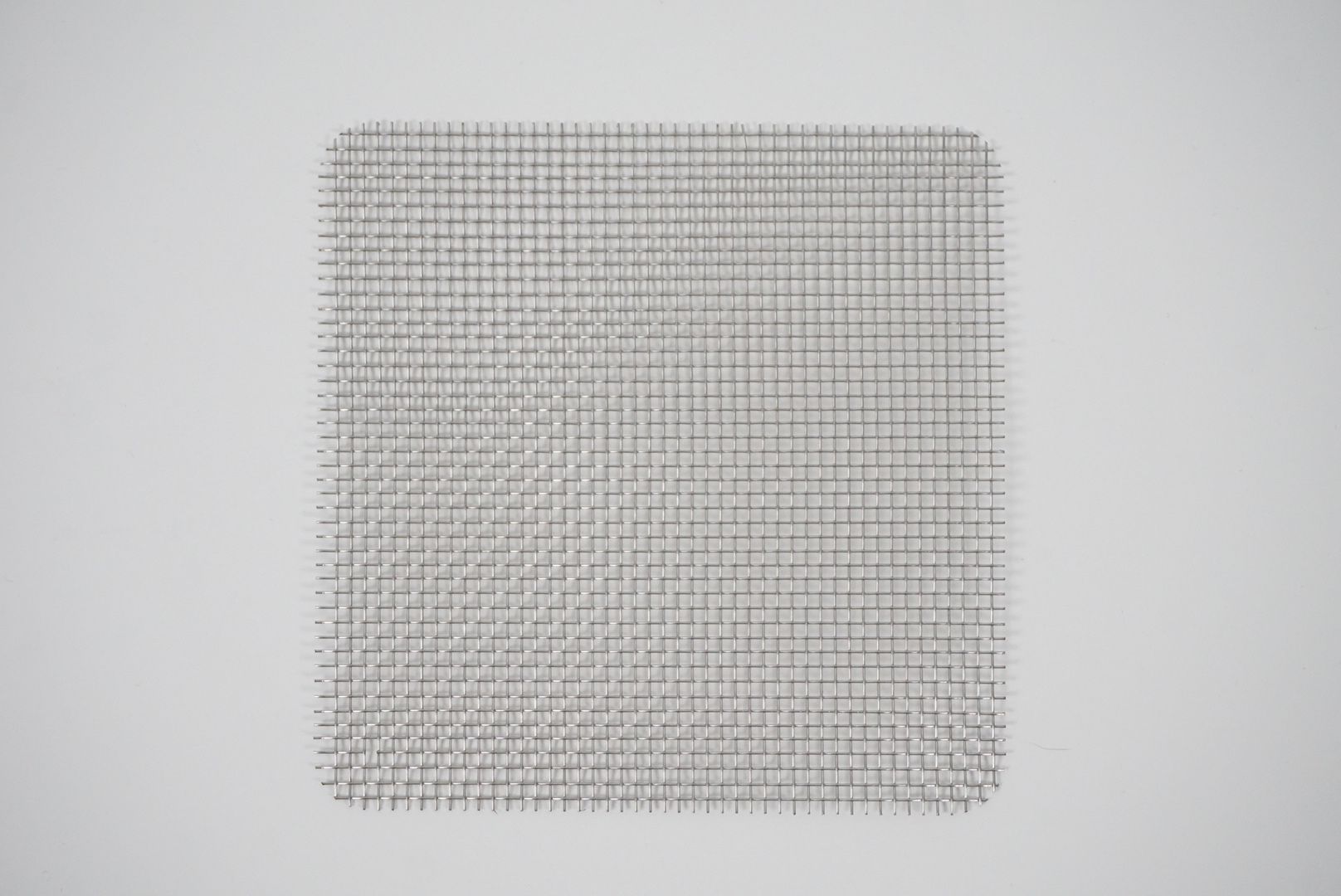

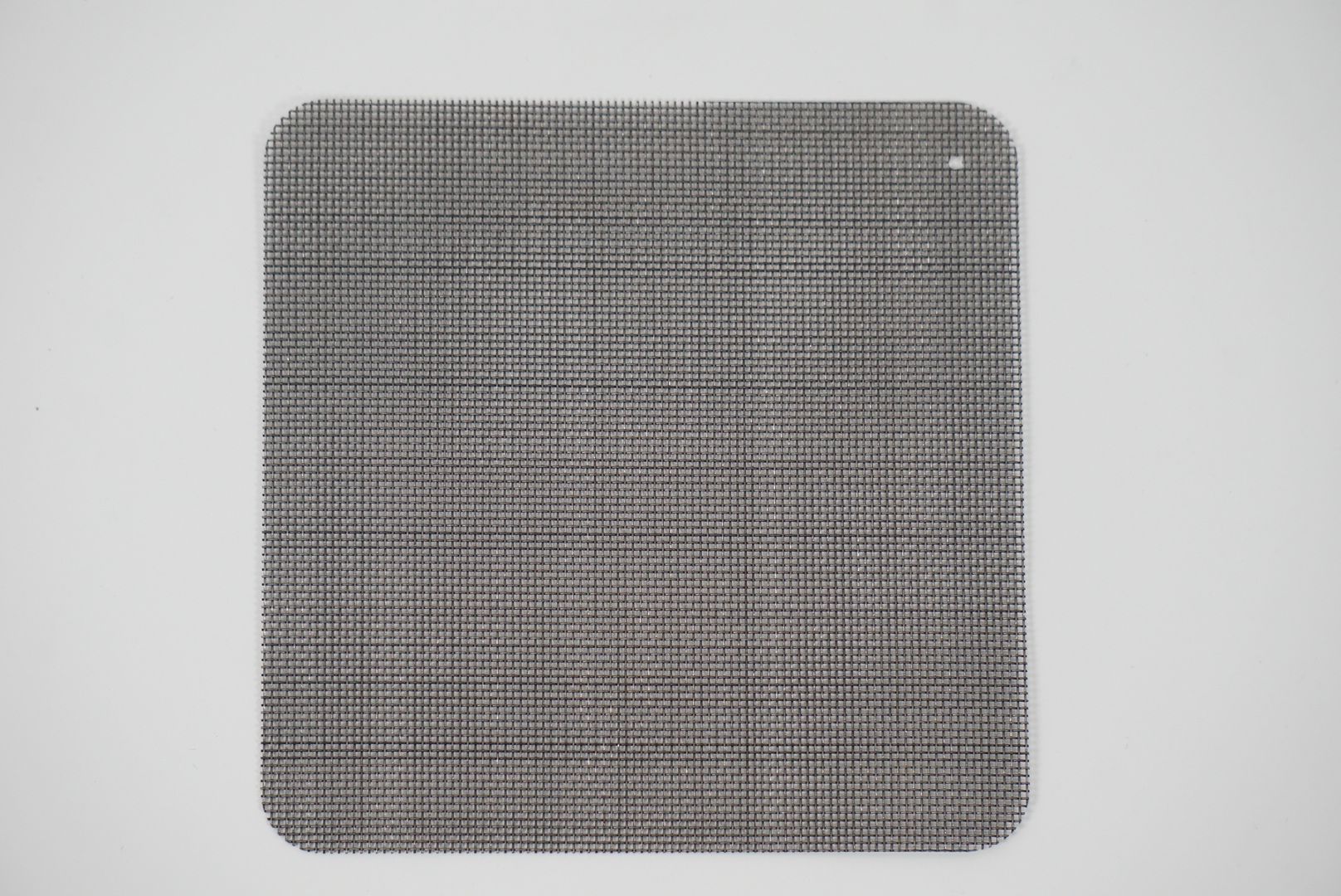

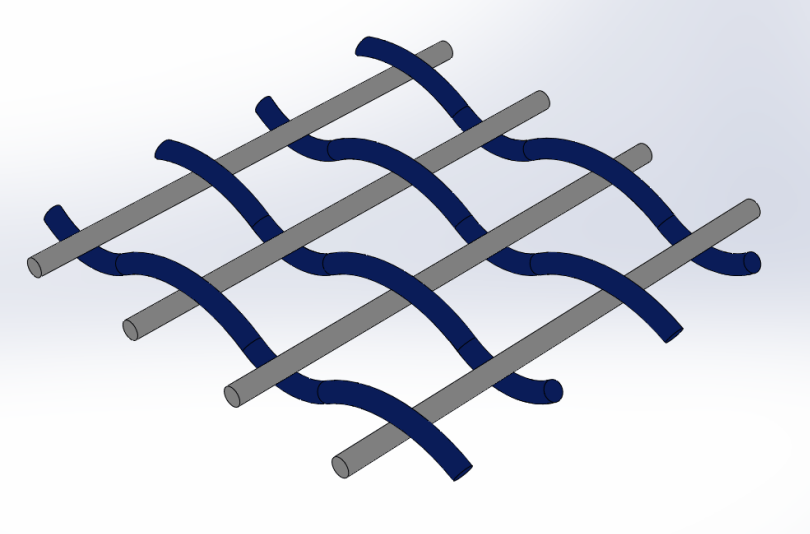

PLAIN weaving for standard meshes

Wire mesh is our core business and has been manufactured since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. We meet the requirements of ISO 3310-1, ISO 9044 and ISO 4783-2 and are ISO 9001 certified. They define:

- Main technical characteristics

- Dimensional tolerances

- Permissible defects and their quantification

- Terms of delivery

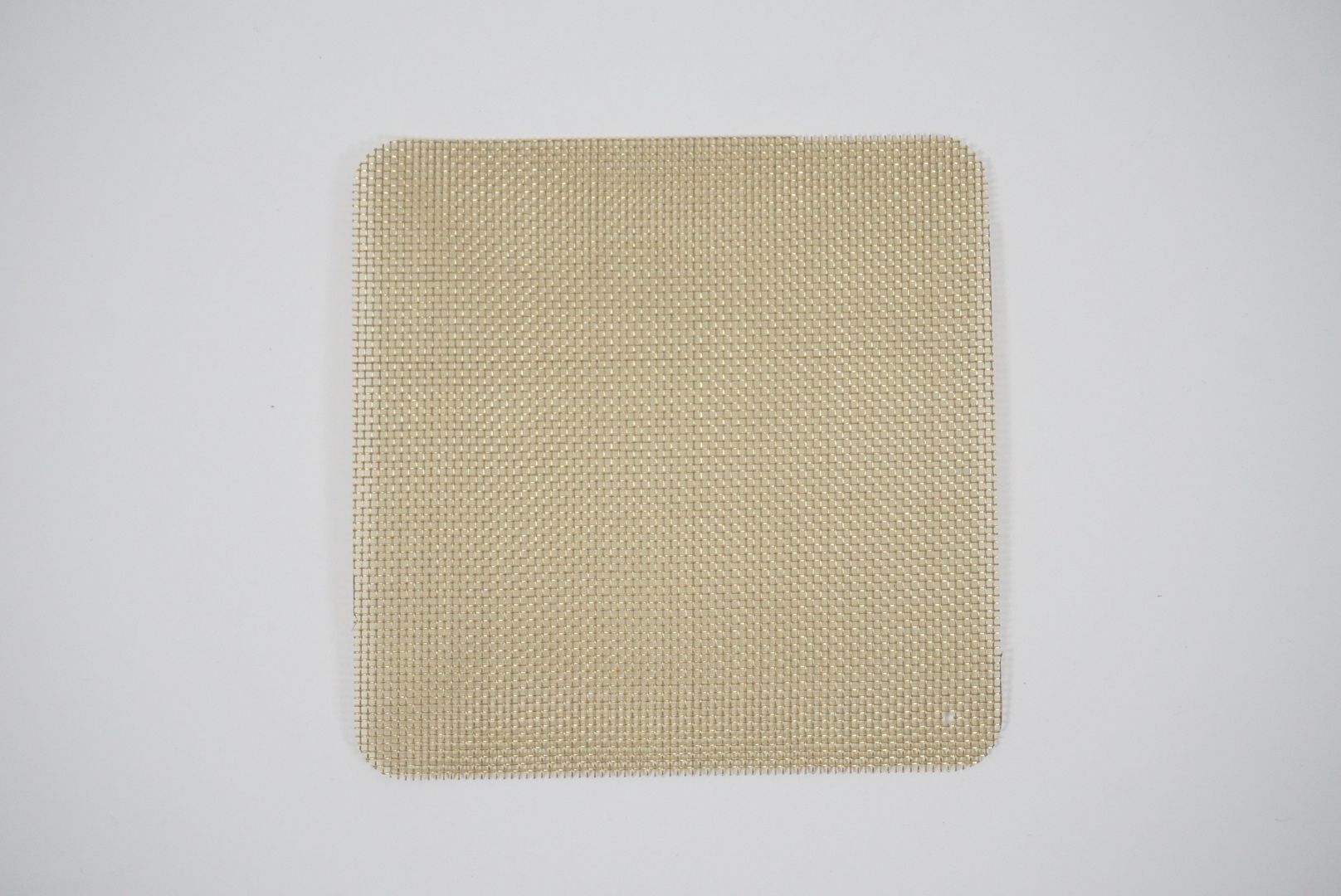

Woven meshes are first stored in rolls. SAULAS carries a large stock to ensure maximum availability. We mainly weave stainless steels, but we can respond quickly in any raw material, depending on wire availability:

- Magnetisable stainless steel – Aisi 430, Aisi 318 LN, adv.

- Refractory stainless steel – Aisi 321, Aisi 327, Inconel, adv.

- Super duplex stainless steel – Uranus 45N (318 LN), adv.

- Annealed steel

- High-strength steel

- Galvanised steel

- Brass, copper

- Gold, titanium, adv.

- PLAIN weave is the most common weave in industry. The geometric shape of the mesh is square and allows perpendicular passage of the product to be sieved or filtered. There are countless combinations between aperture (mesh) and wire diameter in the ISO 9044 standard. The choice is directly linked to your constraints adv. particle size, productivity, strength, price, adv. The following information is needed to specify your mesh and determine its price: Primary material, see above.

- Weft or roll width: from a few mm to 3 meters.

- Warp or length of the roller: from a few to several hundred meters.

- Mesh size or nominal opening, i.e. distance between 2 wires: from 25µ to several mm.

- Wire diameter : from 25µ to several mm.

- Heat treatment (hyperquenching, adv.).

- Expected finish (degreasing, packaging, adv.).

You may have additional information to specify your mesh:

- Mesh is a common feature in Anglo-Saxon companies and meshes. It must come with an additional data : mesh size or wire diameter.

- Nr (number) is a common feature of French and Italian companies and meshes. It must come with an additional data : mesh size or wire diameter.

- Percentage of open area (in %) or the "transparency" which characterises the productivity of your mesh. It must come with an additional data : mesh size or wire diameter.

- Pitch, which corresponds to the mesh + wire diameter.

Meshes are at the heart of all products we manufacture and sell, whether for filtering, sieving, separating, transporting, protecting, or adv ... We take particular care in producing your order in a dedicated workshop, equipped with all tools needed to shape the mesh and its frame, in all sizes.