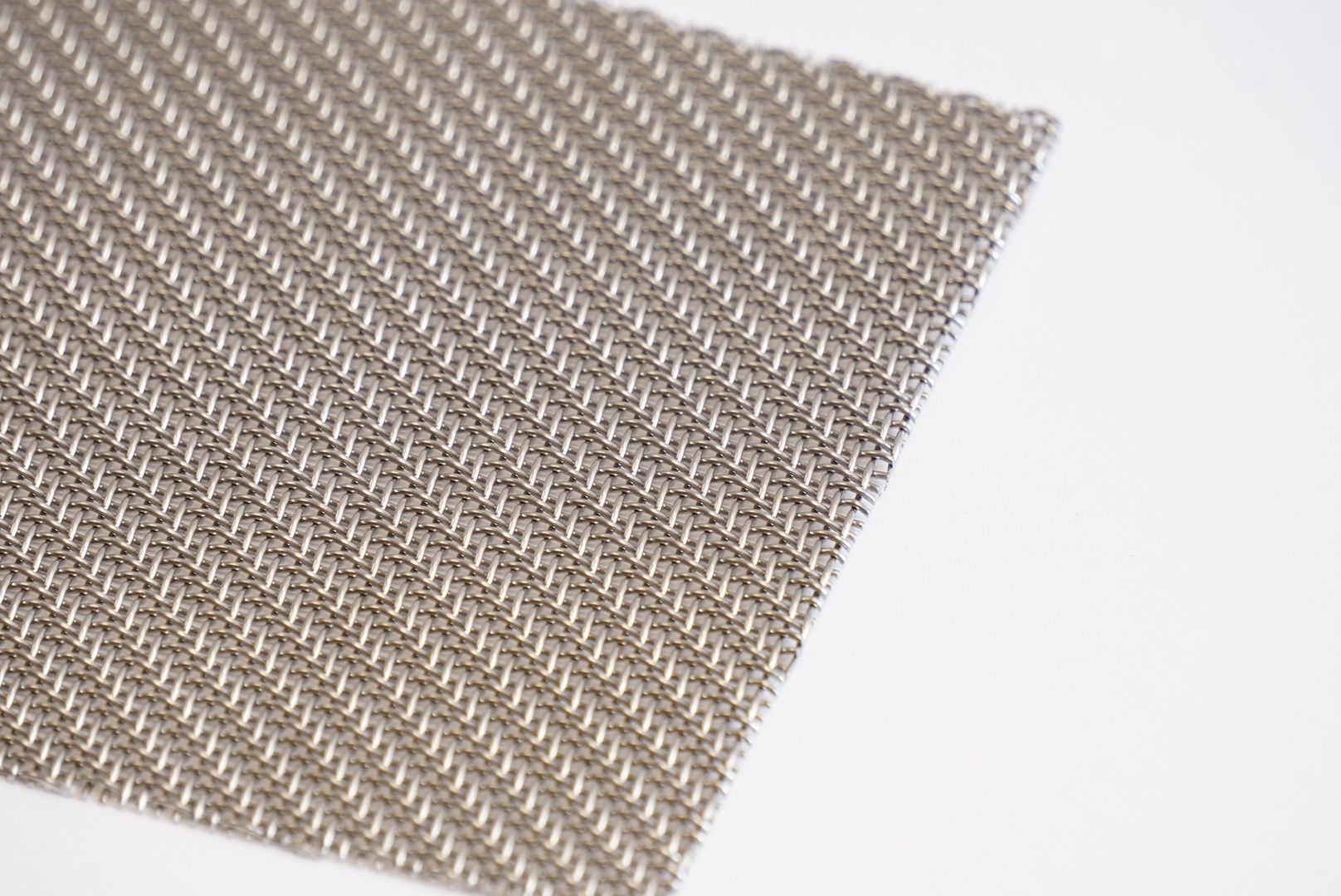

Twilled or Reverse weaving for standard meshes

The twilled or reverse weaving is adapted to specific constraints imposed by the shape of the piece or the mesh required. The geometric shape of the mesh is square or rectangular, allowing perpendicular passage of the product to be sieved or filtered.

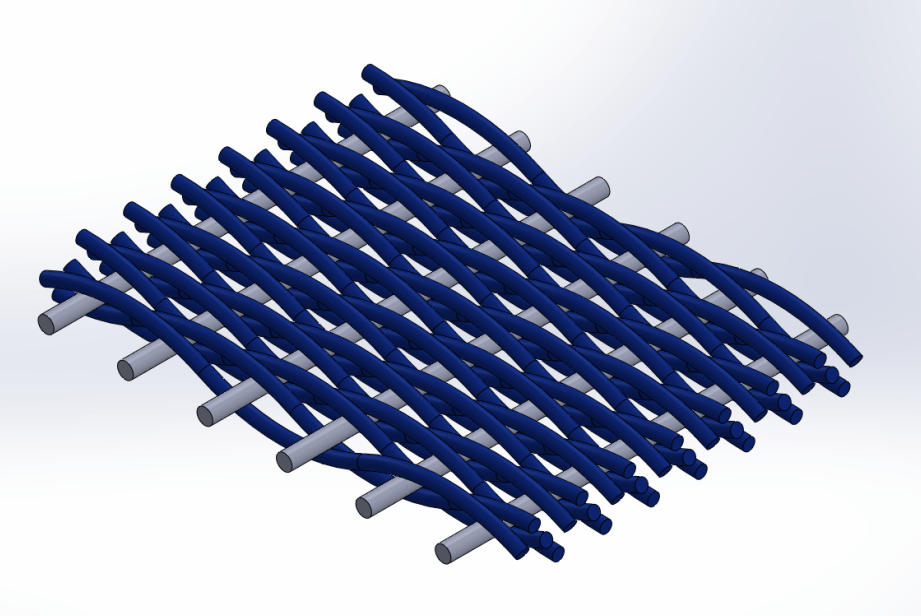

It involves passing each wire under several (2, 3 or 4) wires in the opposite direction, then over one or more wires in the opposite direction, repeatedly. There are many possible combinations. The most common are 2×2 or 4×1.

It gives the wires greater freedom of movement, while guaranteeing perfect knit regularity and great strength.

This freedom of wire movement is required for deep-drawn products (colanders, mould bottoms, adv.) which require the mesh to be highly deformable at certain points.

It is also necessary when the diameter of the wire used is close to, or even greater than, the mesh opening. For example, for very thin meshes such as with a 20 µ # and a Ø 20 µ wire.

In the case of the 4×1, it has a smooth side that makes it easy to remove the filter cake formed or the recycled cardboard tray formed in the mould.

Additional heat treatment, such as hyper-quenching or the use of a special alloy, enhances the deformation and memory properties of these meshes.

There are countless combinations between aperture(mesh) and wire Ø in the ISO 9044 standard. The choice is directly linked to your constraints.

Mesh can be sold in rolls of any width, in panels of any geometric shape and transformed into finished products (filters, frames, cylinders, adv.) of any size.

The following information is needed to specify your mesh and determine its price:

- Raw material,

- Stainless steel: Aisi 304, 304 L, 316, 316 L, 316 TI

- Special stainless steels: magnetisable (430 adv.), refractory (321 adv.), Nitronic, adv.

- Annealed steel

- Galvanised steel

- Nickel, brass, copper, gold, titanium, adv.

- Weft or roll width: from a few mm up to 3 meters.

- Warp or roll length: from a few to several hundred meters.

- Mesh size or nominal opening (w), i.e. the distance between 2 wires: from 20 µ to several mm.

- Wire diameter: from 20 µ to several mm.

- Heat treatment (hyperquenching, adv.).

- Expected finish (degreasing, packaging, adv.).

You may have additional information to specify your mesh:

- Mesh is a common feature in Anglo-Saxon companies. To define your mesh, it must come with by either the mesh size or the thread diameter.

- Nr (number) is a common feature in French and Italian companies. To define your mesh, it must come with either the mesh size or the thread diameter.

- Percentage of open area (in %) or the “transparency” which characterises the productivity of your mesh. To define your mesh, it must be accompanied by the desired mesh.

- Pitch, which corresponds to the mesh + wire Ø.

We are ISO 9001 certified and meet the requirements of ISO 3310-1 (control mesh) or ISO 9044 (industrial mesh) and ISO 4783-2 (preferred combinations # and Ø) standards.

It is the guarantee to get a product of consistent quality, with all required certificates: dimensional, material, alimentary, etc. Welded wire mesh is our core business and has been manufactured since 1960 in our workshop near Troyes, France. SAULAS has always been very involved in standardisation bodies and regularly invests in ever more efficient looms. More than 8,000 customers in France and abroad have already placed their trust in us.